Description

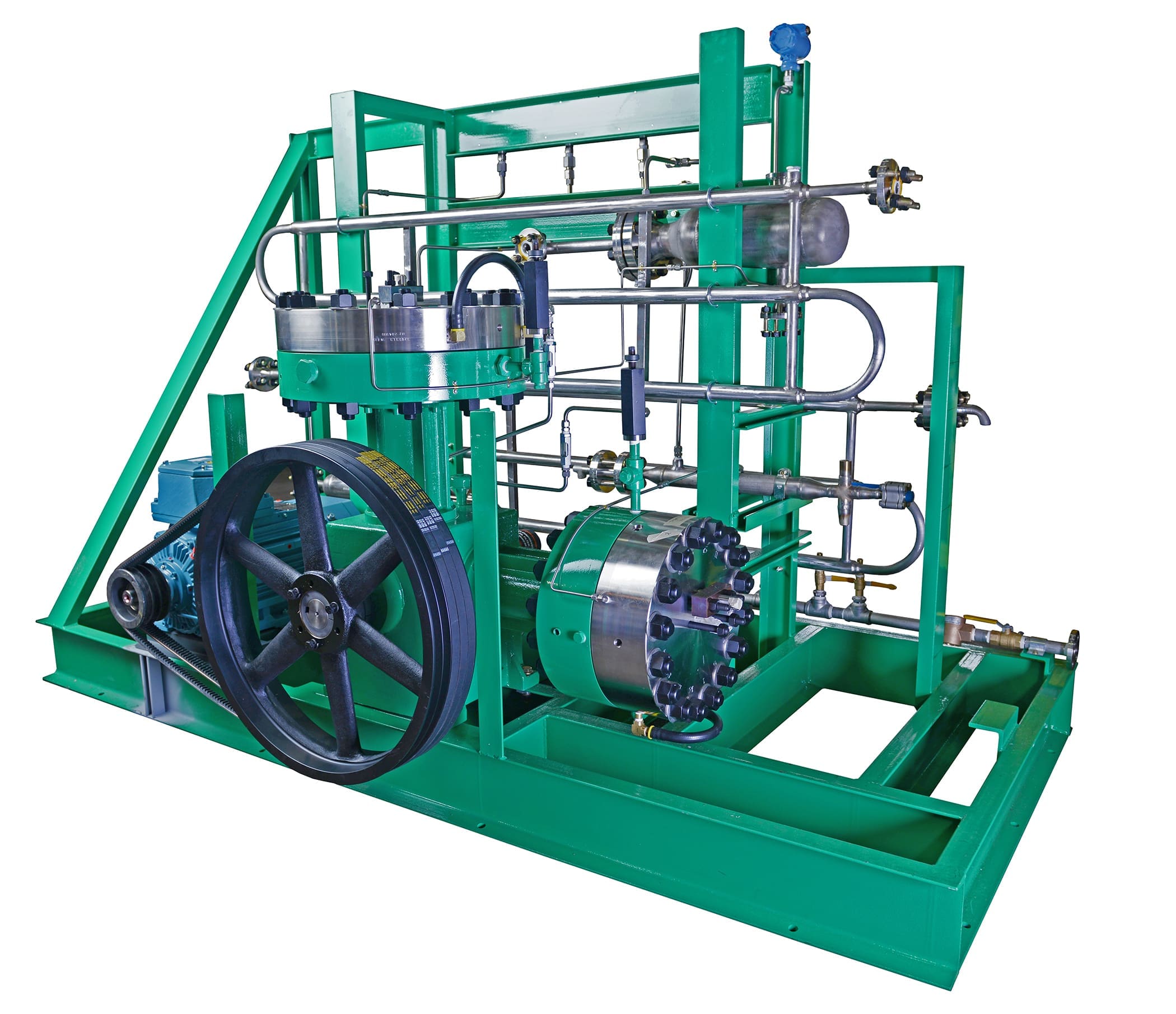

Sundyne Compression Diaphragm Series 4000 – Rugged , Leak ‑ Free High ‑ Pressure Solution (Up to 16,750 psi)

Key Technical Specification

US 60 Hz

Maximum Working Pressure 16,750 psi

Maximum Motor Size 40 HP

Mounting L Configuration

Maximum Displacement 45.9 ft3/min

Speed Range 250 to 400 rpm

Maximum Discharge Temperature 450°F

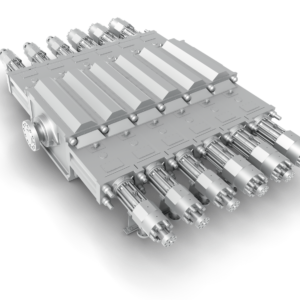

Stroke Length 4.5 in

Process Connection Flanges 0.5 to 1.5 in

Piston Range 0.6 to 7.5 in

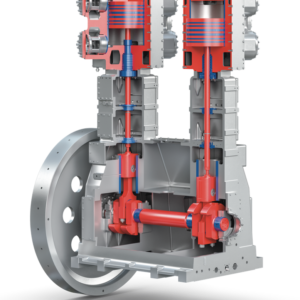

Crankshaft Diameter 2.5 in

Crankpin Diameter 1.25 in

Main Bearing Type Tapered Roller

Crankpin Bearing Type Babbit Sleeve

Wrist Pin Bearing Type Needle

Lubricant-ISO 68

Lubrication Type Pressurized

Sump Capacity 10 Qts

Oil Cooler Not Required

Cooling Type Water Cooled

Why Choose the Series 4000?

Zero‑Leak , Oil ‑ Free Purity

Sealless diaphragm design with static seals prevents gas from contacting moving parts , delivering ultra – pure , zero – contamination performance even with corrosive or hazardous gases

Industry – Leading Pressure Capacity

Capable of reaching pressures up to 16,750 psi (~1,155 bar) in single – or two – stage setups , offering flexible and dependable solutions for demanding applications

Heavy-Duty and Reliable

Utilizes robust crankcase and diaphragm materials from thousands of high – stress deployments – built to survive extreme industrial conditions

Minimal Maintenance , Maximum Uptime

Sealless operation eliminates dynamic seals and external leakage points. Fewer wear parts mean lower maintenance and higher operational reliability

Additional Features

Compact “L” Footprint

Designed for skid installation, it saves space while supporting a wide range of motor power and process flange sizes

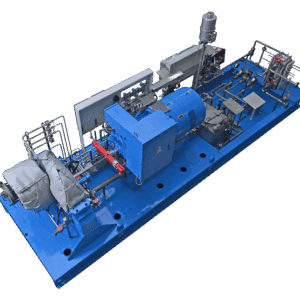

API ‑ 618 Compliant & Customizable

Available in multiple configurations and stages , and built to API specifications for critical industrial use

Advanced Diaphragm Life

Proprietary diaphragm and cavity designs ensure exceptional fatigue life – expect reliable operation through years of continuous use

Global Service Support

Backed by Sundyne’s international network , ensuring prompt delivery of genuine parts and maintenance expertise

Applications

Petrochemical & Refining – Ideal for processing ammonia , chlorine , or volatile petrochemicals

Specialty & Electronic Gases – Supports ultra – pure , contamination – free compression for semiconductor , pharmaceutical , and lab environments

Hydrogen Processing & CCUS – Handles hydrogen and CO₂ in capturing , recycling , or injection processes

Research & Pilot Plants – Perfect for R&D and pilot – scale systems requiring taut control and high pressure

Upgrade to the Sundyne Series 4000 diaphragm compressor – your compact , high-pressure , and leak – free solution. With industry – leading 16,750 psi performance , API – grade customization , low maintenance , and global support , it’s the dependable choice for ultra – pure , critical gas applications.