Description

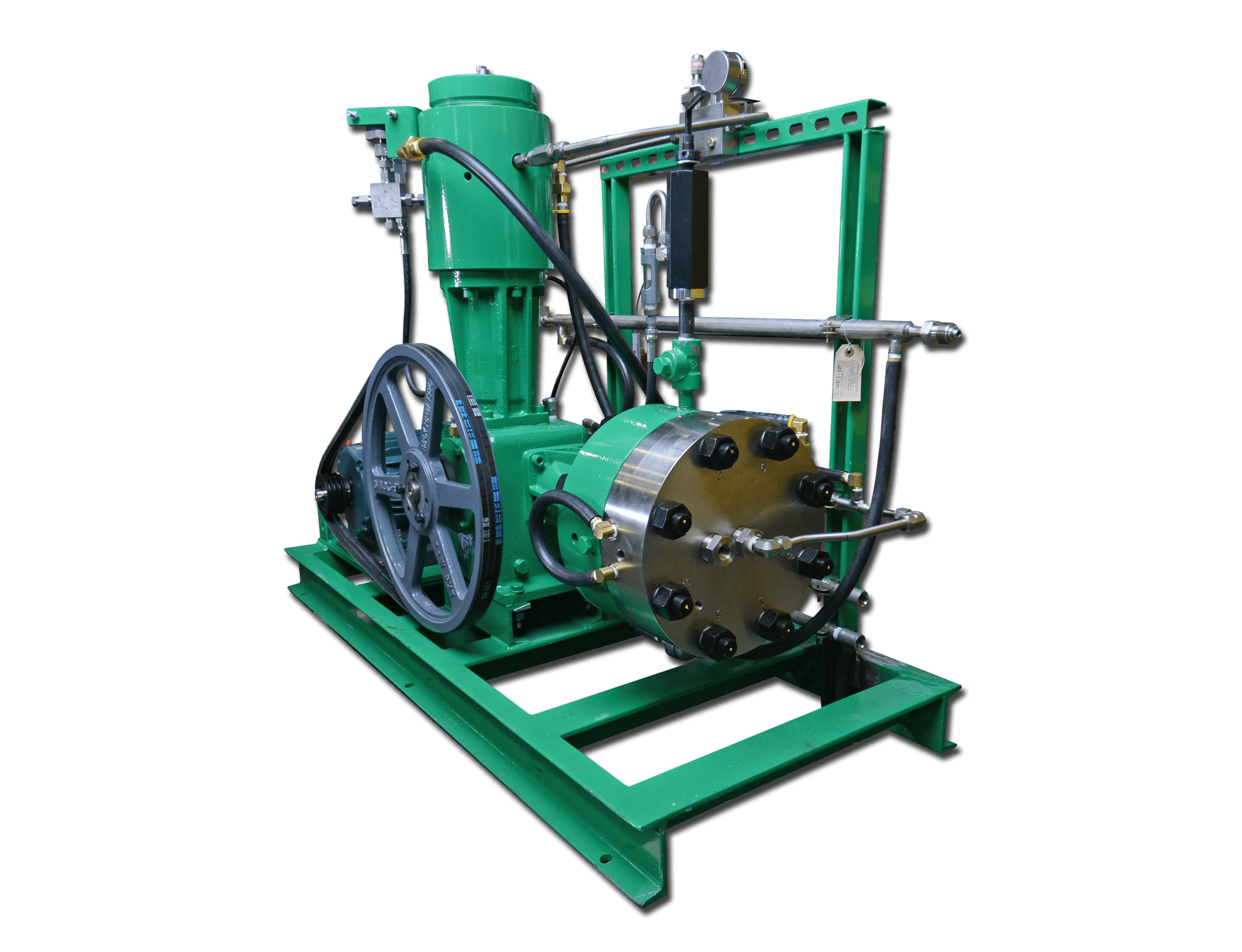

Sundyne Compression Diaphragm Series 2000 – Compact , Leak ‑ Free High ‑ Pressure Solution (Up to 1,035 bar)

Key Technical Specification

US 60 Hz

Maximum Working Pressure 15,000 psi

Maximum Motor Size 15 HP

Mounting L Configuration

Maximum Displacement 7.1 ft3/min

Speed Range 250 to 450 rpm

Maximum Discharge Temperature 475°F

Stroke Length 2.5 in

Process Connection Flanges 0.5 to 1.5 in

Piston Range 0.3 to 3.5 in

Crankshaft Diameter 1.5 in

Crankpin Diameter 1 in

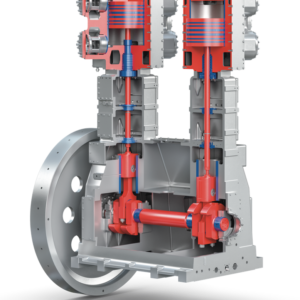

Main Bearing Type Tapered Roller

Crankpin Bearing Type Babbit Sleeve

Wrist Pin Bearing Type Needle

Lubricant-ISO 68

Lubrication Type Pressurized

Sump Capacity 3 Qts

Oil Cooler Not Required

Cooling Type Water Cooled

Why Choose the Series 2000?

Zero-Leak , Oil – Free Purity

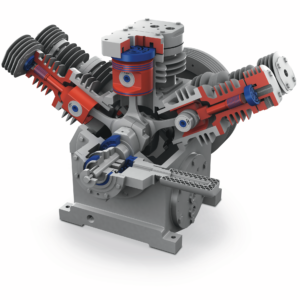

Innovative diaphragm design with static seals ensures total isolation between gas and mechanical parts – no leaks , no contamination. Ideal for ultra ‑ pure , corrosive , or hazardous gases.

High-Pressure Reliability

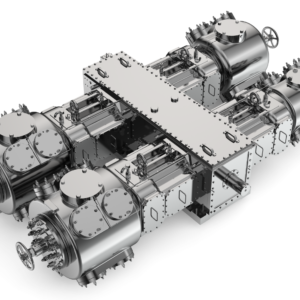

Handles operating pressures up to 15,000 psi (≈1,035 bar) , available in single – or two – stage layouts , offering precision and robustness under demanding conditions.

Minimal Maintenance & Low Noise

With static seals and fewer moving parts , it runs quietly and with less upkeep – reducing downtime and total cost of ownership.

Built for Safety

Constructed from corrosion – resistant alloys and designed with triple – diaphragm construction and leak detection to safely handle toxic or reactive gases.

Additional Features

Compact “L” Configuration – Small footprint with motor options up to 15 hp and ½″ – 1″ process connections, perfect for tight installations

API 618 & Customizable – Built to industry standards and available in various configurations to precisely match your application.

Advanced Leak Detection – Triple-diaphragm design with O ‑ ring sealed leak detection anticipates failure before it becomes a hazard.

Quiet & Efficient Operation – Hydraulic – assisted diaphragms and durable components deliver smooth, energy – efficient performance.

Applications

Chemical & Petrochemical – Safely compresses reactive gases like ammonia , chlorine , and hydrogen chloride.

High-Purity Gas Systems – Trusted in electronics , pharma , specialty gases , and food industries where zero contamination is critical .

Hydrogen & Carbon Capture – Ideal for hydrogen compression (e.g. , fuel cells) and CO₂ handling in CCUS projects .

Oil & Gas Support – Used for refinery boosters , methane recovery , and gas injection duties .

Choose the Sundyne Series 2000 diaphragm compressor for a compact , ultra‑pure , and leak ‑ free solution – delivering up to 1,035 bar of reliable performance with minimal maintenance , maximum safety , and quiet operation.