Description

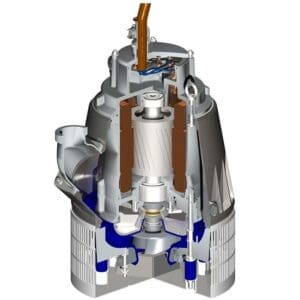

Sulzer Centrifugal Submersible dewatering pumps Submersible sludge pumps JS 4, JS 7, JS 8 -Take control of your sludge pumping

Key Technical Specifications:

| Electric submersible pump | JS 4 W |

| Maximum submergence | 7 m |

| Protection class | IP 68 |

| pH of the pumped medium | 6.5 – 8.5 |

| Strainer hole | 6 mm |

| Motor range P2 | 0.4 kW, 1~ |

| Speed | 2’850 rpm |

| Power cable | 10 m H07RN8-F |

| Electric submersible pump | JS 7 W |

| Maximum submergence | 7 m |

| Protection class | IP 68 |

| pH of the pumped medium | 6.5 – 8.5 |

| Strainer hole | 6 mm |

| Motor range P2 | 0.75 kW, 1~ |

| Speed | 2’850 rpm |

| Power cable | 10 m H07RN8-F |

| Electric submersible pump | JS 8 W |

| Maximum submergence | 7 m |

| Protection class | IP 68 |

| pH of the pumped medium | 6.5 – 8.5 |

| Strainer hole | 6 mm |

| Motor range P2 | 0.75 kW, 1~ |

| Speed | 2’850 rpm |

| Power cable | 10 m H07RN8-F |

Why Choose the Sulzer JS 4 , JS 7 , JS 8 Sludge Pumps

Designed for pumping slurry , sludge , and abrasive water in environments such as construction sites , tunneling , quarries , and mining operations.

Equipped with a shaft‑mounted agitator to prevent clogging and eliminate air-lock risks.

Built‑in float switch level control enables fully automatic plug‑and‑pump setup with dry‑run protection and pump auto-start functionality.

Lightweight yet robust nodular cast‑iron hydraulic components ensure durability and ease of handling.

Technical Specifications (60 Hz version approximate equivalents)

Key Features & Advantages

Plug‑and‑pump ready with integrated float switch and thermal motor protection , simplifying setup and minimizing operator oversight.

Reliable sealing with double silicon carbide mechanical seals in oil bath and sealed ball bearings ensure long-term durability in abrasive conditions.

Portable and lightweight , easy to transport and maneuver in tight or remote work environments.

Wear‑resistant hydraulics , using vortex impeller design and durable cast‐iron surfaces to handle sludge and solids reliably.