Description

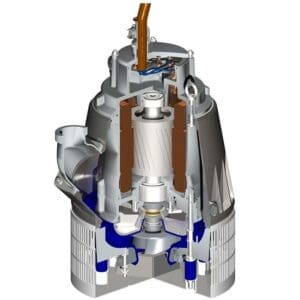

Sulzer Centrifugal Submersible dewatering pumps Submersible sludge pump XJS 110 -Smooth operators

Key Technical Specifications:

50Hz

| Electric submersible pump | XJS 110 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Free passage | 48 x 60 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 11.8 kW |

| Speed | 2,920 rpm |

| Power cable | 20 m type H07RN8-F |

60HZ

| Electric submersible pump | XJS 110 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Free passage | 48 x 60 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 13.5 kW |

| Speed | 3,500 rpm |

| Power cable | 20 m type H07RN8-F |

Why Choose the Sulzer XJS 110 Sludge Pump?

This pump is built for heavy-duty dewatering of sludge and abrasive water containing solids. It features a clog-resistant free-flow vortex impeller and volute to ensure uninterrupted operation—even with suspended solids. As a plug-and-pump unit , it requires no external control panel and includes robust thermal protection built into the motor. An optional AquaTronic electronic control system provides automatic phase-rotation correction , motor overload and heat protection , anti-clog reverse spin , and USB diagnostics for operating history and fault logs.

Key Characteristics

Compact and portable at approximately 80 kg (176 lb) without cable.

IP 68-rated casing allows submersion up to about 20 m (65 ft).

Engineered for continuous operation in fluid temperatures up to around 40 °C (104 °F) , fluid densities up to ~1,100 kg/m³, and pH ranges between 5 and 8.

Protects against thermal and overload conditions with stator-mounted sensors rated to stop the pump if the motor exceeds safe temperature thresholds.

Accepts large solids (approximately 48 × 60 mm free passage) to handle grit-laden or viscous media without clogging.

Supports up to 30 starts per hour , making it suitable for level-activated or intermittent duty.

Maintenance-friendly , with modular hydraulic and motor assemblies , oil-bath seal inspection ports, and accessible electrical junction box.

Dual mechanical shaft seals with silicon-carbide surfaces immersed in oil bath offer superior abrasion resistance and long-term reliability.