Description

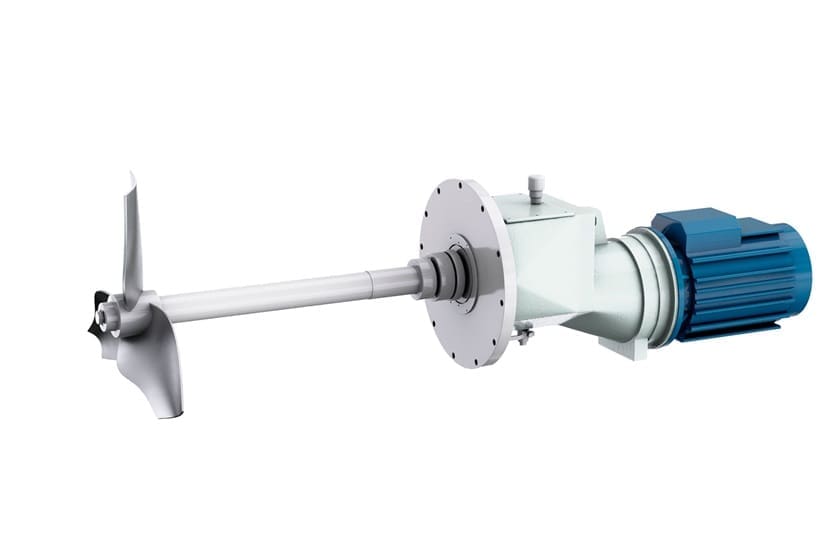

Sulzer Agitators and mixers Horizontal agitators SALOMIX™ SLR/STR side-mounted agitators -Mix and match – efficient mixing technology

Key Technical Specifications:

| Propeller diameters | 315 – 800 mm / 12.4 – 31.5 in |

| Power | 2.2 – 11 kW / 3 – 15 hp |

| Maximum speed of rotation | Up to 470 rpm |

| Performance range | SALOMIX SLR/STR agitators have a wide and comprehensive hydraulic coverage which enables their use in all mixing applications. |

| Stock concentration | Up to 6 % |

Why Choose Sulzer SALOMIX™ SLR / STR Side-Mounted Agitators?

The SALOMIX™ SLR and STR series are heavy-duty side-mounted agitators engineered for demanding industrial mixing applications. Designed for maximum torque capacity , long service life , and reliable performance , they handle high-viscosity fluids , abrasive slurries , and challenging solids suspension tasks with ease. Their robust gearbox-driven design ensures optimal power transmission , while advanced sealing options protect against leakage in harsh operating conditions.

Key Technical Specifications

Mounting Type: Side-mounted horizontal configuration for large tanks and basins

Drive System: Gear-driven for high torque output and efficient mixing of viscous or dense media

Impeller Type: High-efficiency SALOMIX™ impellers (hydrofoil , pitched-blade , or custom) designed for strong axial or radial flow patterns

Materials & Build:

Wetted parts in stainless steel , duplex steel , or coated carbon steel for superior wear and corrosion resistance

Heavy-duty shaft and bearing arrangement for high load capacity and vibration stability

Shaft sealing options include single , double , or cartridge mechanical seals for maximum reliability

Maintenance Features: Designed for quick seal and bearing service with minimal downtime

Operating Limits

Power Range: From 5 kW to over 500 kW depending on model and process needs

Shaft Length: Custom-configured to match tank geometry and mixing requirements

Impeller Diameter: Optimized to achieve required flow and suspension characteristics

Operating Temperature: Up to +200 °C (material dependent)

Operating Pressure: According to tank design and sealing specification

Typical Applications

Mining and mineral processing for abrasive slurry mixing and solids suspension

Pulp and paper industry for stock agitation and bleaching processes

Petrochemical and chemical industries for blending high-viscosity or multiphase fluids

Water and wastewater treatment for sludge mixing and chemical blending in large basins

Fermentation and biofuel processes requiring strong, consistent agitation

Additional Features

Gear-driven design ensures high torque handling for viscous and heavy-duty applications

Rugged construction withstands demanding process conditions and continuous operation

Flexible sealing configurations to suit abrasive , corrosive , or high-temperature fluids

Modular design allows customization for impeller type , shaft length , and drive arrangement

Built for long maintenance intervals and reduced lifecycle cost