Description

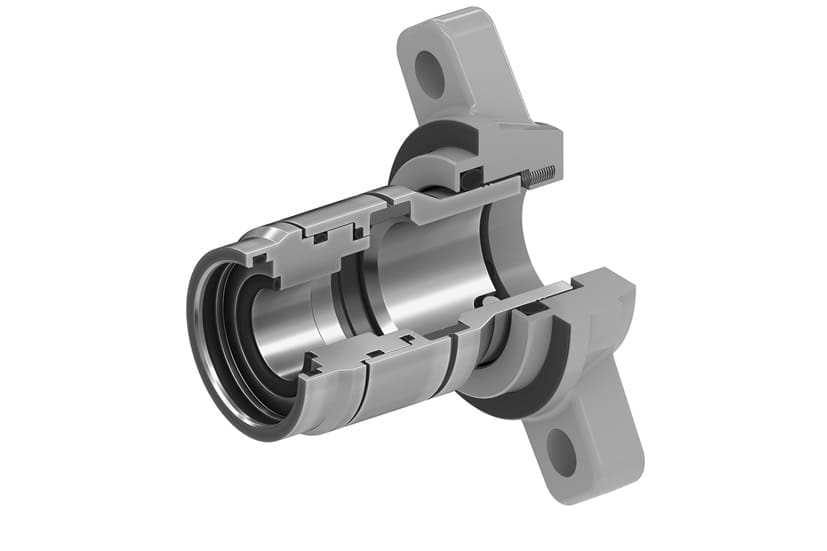

Sulzer Mechanical seals and accessories Ready-fitted seals -TB mechanical seals for reliable operation and fast and easy maintenance

Key Technical Specifications:

| TB1 | TB1F | TB2P | |

| P max | 25 bar / 362 psi | 25 bar / 362 psi | 25 bar / 362 psi |

| V max | 25 m/s / 82 ft/s | 25 m/s / 82 ft/s | 25 m/s / 82 ft/s |

| T max | 125°C / 257°F | 120°C / 284°F with internal flushing180°C / 355°F with external flushing |

180°C / 355°F |

| Seal faces |

SiC/SiC, C/SiC | SiC/SiC, C/SiC | SiC/SiC-SiC/SiC SiC/SiC-C/SiC |

| O-rings |

EPDM, FKM | EPDM, FKM | EPDM, FKM |

| Other parts |

AISI 316, AISI 329 | AISI 316, AISI 329 | AISI 316, AISI 329 |

Why Choose Sulzer Ready-Fitted Mechanical Seals?

Sulzer Ready-Fitted Seals are pre-assembled cartridge units designed to provide rapid installation, reduced downtime , and reliable sealing performance without the need for on-site assembly. Each seal is engineered to match specific Sulzer pump models , ensuring perfect compatibility , optimum alignment , and consistent operational reliability. The factory-tested design minimizes human error during installation , extending service life and improving pump efficiency.

Key Technical Specifications

Seal Format: Pre-assembled cartridge mechanical seal for direct pump fitment

Compatibility: Tailored for Sulzer pump series , ensuring precise axial and radial positioning

Materials & Design:

Seal faces in premium-grade silicon carbide or tungsten carbide for wear resistance

Secondary seals in high-performance elastomers for chemical and temperature resistance

Springs and metal parts in corrosion-resistant stainless steel or alloy for extended durability

Mechanical Integrity: Balanced design to minimize face loading and handle high pressure fluctuations

Installation Efficiency: Factory pre-set working length and compression – no field adjustment required

Operating Limits

Shaft Diameter: As per specific Sulzer pump model (typically 25 mm – 100 mm)

Pressure Rating: up to 25 bar(g) depending on seal size and configuration

Speed: up to 25 m/s

Temperature Range: –20 °C to +180 °C (material dependent)

Typical Applications

Sulzer centrifugal pumps in water treatment , power generation , and general industry

Process pumps in chemical , petrochemical , and refinery operations

Slurry-handling and abrasive-fluid applications with hardened face options

High-temperature and high-pressure liquid handling where precision sealing is critical

Additional Features

Pre-fitted design eliminates assembly errors and reduces commissioning time

Precisely machined tolerances for perfect seal face contact and leak prevention

Cartridge format allows quick change-out without dismantling pump components

Compatible with single , double , or tandem seal arrangements for various duty requirements

Factory-tested for leakage , pressure , and alignment before dispatch

Sulzer Ready-Fitted Mechanical Seals deliver a seamless, high-performance sealing solution engineered for direct pump compatibility. With their precision-machined, pre-assembled cartridge format, they ensure fast installation , minimal downtime , and consistent sealing reliability across the most demanding industrial environments. Built with advanced materials and designed for long-term durability , these seals protect both your pump and your process , keeping operations efficient , safe , and cost-effective.