Description

Sulzer Centrifugal Between bearing pumps MC high-pressure stage casing pump -High-pressure pump designed to your spec

Key Technical Specifications:

| 50 Hz | 60 Hz | |

| Discharge sizes | up to 350 mm | up to 14 in. |

| Capacities | up to 1,860 m3/h | up to 9,720 US gpm |

| Heads | up to 1,750 m | up to 5,500 ft. |

| Pressures | up to 180 bar | up to 2,610 psi |

| Temperatures | up to 180°C | up to 356°F |

Why Choose Sulzer MC High-Pressure Stage Casing Pumps?

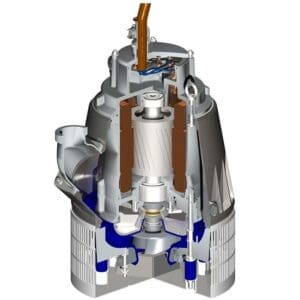

The Sulzer MC pump is a robust , multistage centrifugal pump engineered for high-pressure applications in power generation, water treatment , and general industry. Its radially split , ring-section design ensures easy maintenance, high reliability , and long service life, even under severe operating conditions. Trusted globally, the MC pump is a go-to solution for boiler feedwater and high-demand transfer duties.

Key Technical Specifications

Pump Type: Horizontal multistage centrifugal pump , between bearings

Design: Radially split, multistage ring-section casing

Impeller: Closed radial impellers , dynamically balanced

Seal Options: Single/double mechanical seals , API/ISO compliant

Bearings: Sleeve or antifriction type , with oil lubrication

Design & Functionality

Engineered for high-pressure continuous-duty applications

Multiple impellers for achieving high heads with excellent efficiency

Robust construction handles high thermal and mechanical loads

Axial thrust balanced by opposed impeller arrangement or balance drum

Compact footprint supports flexible system integration

Typical Applications

Boiler feedwater pumping in thermal and combined-cycle power plants

Feed duties in desalination (MED and MSF) and high-pressure water systems

High-pressure transfer in chemical and general industries

Condensate and high-pressure cleaning water circuits

District heating and water injection systems

Additional Features

Axially split wear rings and replaceable casing liners extend service life

Rugged rotor design supports thermal growth and alignment stability

Multiple seal plans available for safety and environmental compliance

Optimized hydraulics reduce energy use and NPSHr

Designed for minimal vibration and smooth , quiet operation