Description

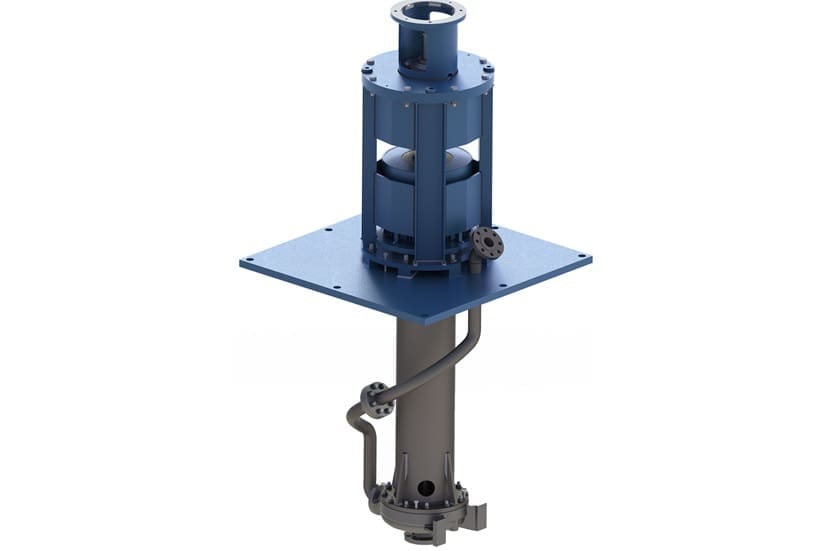

Sulzer Centrifugal Vertically suspended pumps Heavy-duty cantilever sump pump type Ensival Moret VAP – Durability for pumping demanding liquids and slurry

Key Technical Specifications:

| Capacities | up to 3’500 m3/h / 15’400 USgpm |

| Heads | 150 m / 500 ft. |

| Pressures | up to 20 bar / 290 psi |

| Temperatures | up to 900°C / 1‘652°F |

Why Choose Sulzer Ensival Moret VAP Heavy-Duty Cantilever Sump Pumps?

The Ensival Moret VAP is engineered for continuous operation in severe sump applications , handling abrasive , corrosive , and particle-laden liquids with confidence. Its cantilever shaft design eliminates submerged bearings and seals , ensuring high reliability and minimal maintenance in the toughest environments.

Key Technical Specifications

Pump Type: Vertically suspended single-stage heavy-duty sump pump

Design: Overhung cantilever shaft without submerged bearings or shaft seal

Mounting: Top plate mounting over open or closed sumps

Shaft Length: Up to 4.5 meters

Materials: Wide range including duplex , high-chrome , stainless steel , and custom alloys

Design & Functionality

Open impeller design for solids handling

Heavy-duty shaft minimizes deflection and increases bearing life

No lower bearings or shaft seals—ideal for dirty , abrasive , or corrosive fluids

Optional suction extension pipe for deeper sumps

Vibration-resistant construction for harsh industrial settings

Typical Applications

Mining and mineral processing sumps

Chemical and fertilizer plant pits

Steel and metallurgical slurries

Power station ash handling

Effluent and wastewater pits containing solids or corrosives

Additional Features

High-strength cantilever shaft allows dry running without damage

Solids-resistant open impeller for handling slurries or fouling fluids

Optional strainers or vortex inducers to reduce clogging

No need for shaft sleeve , lip seals , or flush systems

Extended bearing life thanks to rigid design and oversized support

The Sulzer Ensival Moret VAP delivers heavy-duty pumping power in the most aggressive sump environments. With no lower bearings or seals to fail , it offers unmatched reliability , easy maintenance , and long service life. Ideal for slurry-laden , corrosive , or abrasive applications , the VAP sets the standard for vertical cantilever pump performance in industrial operations.