Description

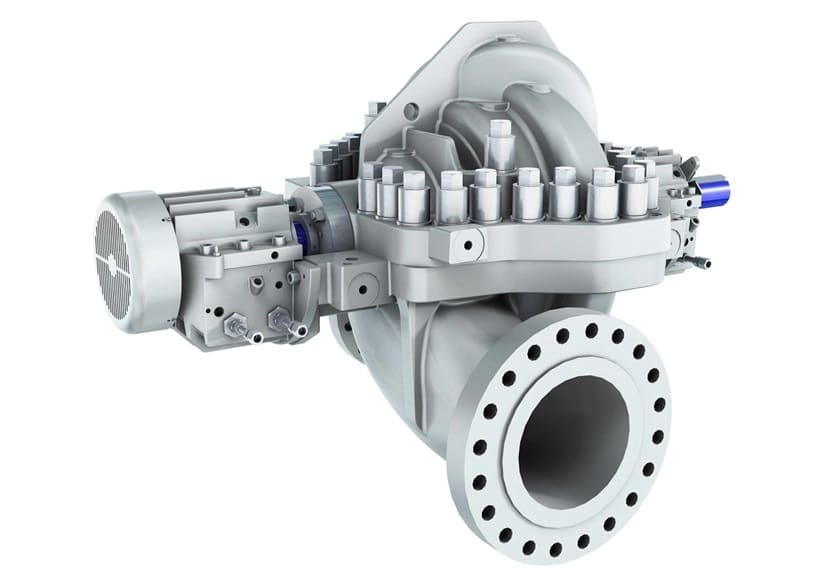

Sulzer Centrifugal Between bearing pumps MSD-RO axially split multistage pump -Our high pressure solution for desalination applications

Key Technical Specifications:

| Capacities | Up to 1,600 m3/h / 7,000 US gpm |

| Heads | Up to 650 m / 2,150 ft |

| Pressures | Up to 90 bar / 1,305 psi |

| Temperatures | Up to 60°C / 140°F |

| Maximum speed of rotation | Up to 3,600 rpm |

Why Choose Sulzer MSD-RO Axially Split Multistage Pump?

The Sulzer MSD-RO is a specialized variant of the trusted MSD pump series , optimized for high-pressure reverse osmosis (RO) applications in desalination plants. Designed with a focus on efficiency , corrosion resistance , and continuous-duty reliability , the MSD-RO delivers exceptional performance under extreme hydraulic loads. It meets the rigorous demands of seawater treatment processes where high pressure and minimal downtime are essential.

Key Technical Specifications

Pump Type: Between-bearings , axially split , multistage centrifugal pump

Impeller Type: Closed , single or double-suction first stage (depending on NPSH requirement)

Casing Design: Horizontally split for easy inspection and service

Standards Compliance: API 610 (BB3) , ISO 13709

Materials of Construction:

– Casing: Duplex or super duplex stainless steel for high corrosion resistance

– Impellers: Duplex or super duplex

– Shaft: High-strength stainless steel with replaceable sleeves

Bearings: Sleeve or tilting-pad bearings , forced oil lubrication

Seal Options: Engineered API mechanical seal systems for high salinity environments

Design & Functionality

Engineered for continuous high-pressure RO service

Optimized hydraulics reduce energy consumption and ensure stable operation

Double-suction first-stage impeller (optional) minimizes NPSHr for seawater feed

Axially split design enables rapid access to rotating elements

Wear rings and balanced hydraulic design extend lifecycle and efficiency

Designed to handle brine with high chloride content without corrosion

Reverse osmosis seawater desalination (SWRO)

High-pressure brine recirculation

Large-scale municipal and industrial water treatment plants

Utility water feed in coastal or offshore facilities

Additional Features

Built for low-maintenance , round-the-clock operation in aggressive marine environments

Superior metallurgy resists pitting , crevice corrosion , and chloride stress cracking

Custom hydraulics tailored to specific membrane system requirements

Compact design minimizes footprint in crowded RO skids or pump rooms

Long MTBF and low life-cycle cost due to rugged construction and optimized design