Description

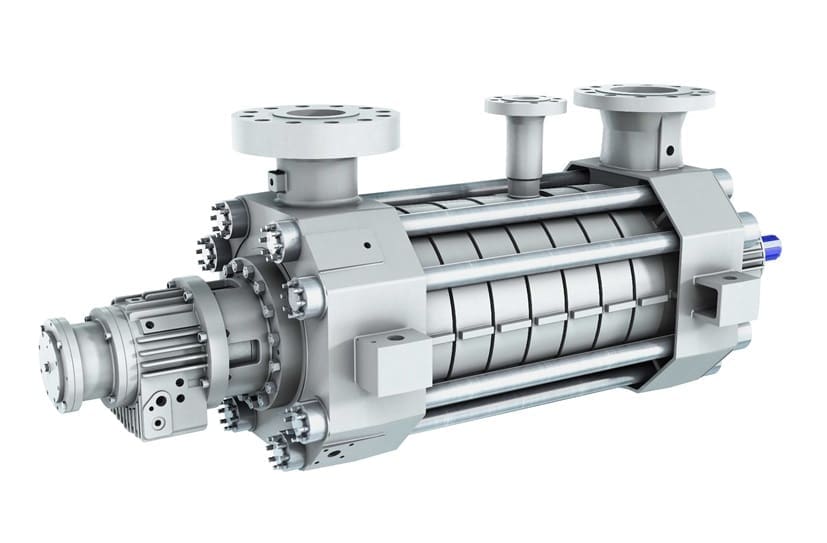

Sulzer Centrifugal Between bearing pumps MD high-pressure stage casing pump -Customized high-pressure pump with clever modular design

Key Technical Specifications:

| 50 Hz | 60 Hz | |

| Discharge sizes | up to 200 mm | up to 8 in |

| Capacities | up to 1,200 m3/h | up to 5,300 US gpm |

| Heads | up to 2,800 m | up to 9,200 ft |

| Suction pressures | up to 50 bar | up to 725 psi |

| Discharge pressures | up to 350 bar | up to 5,080 psi |

| Temperatures | up to 210°C* | up to 410°F* |

Why Choose Sulzer MD High-Pressure Stage Casing Pumps?

The Sulzer MD pump is designed for high-pressure applications that demand precision , performance , and durability. Its horizontal multistage ring-section design offers excellent hydraulic efficiency and mechanical reliability. The MD pump is ideal for continuous operation in critical utility and industrial services , ensuring minimal downtime and long service intervals.

Key Technical Specifications

Pump Type: Horizontal multistage centrifugal pump

Design: Radially split ring-section casing

Impeller: Closed radial impellers

Seal Options: Single or double mechanical seals per API or ISO standards

Bearings: Sleeve or antifriction bearings with forced oil lubrication

Design & Functionality

Modular design for flexibility in pressure and flow range

Precision-engineered impellers deliver high hydraulic performance

Axial thrust balanced via opposed impeller arrangement or balance device

Ring-section casing allows easier maintenance and parts replacement

Rigid rotor construction enables high-speed operation with stability

Typical Applications

Boiler feedwater for thermal and industrial power plants

High-pressure water injection systems

Condensate and cooling water circuits

Desalination and reverse osmosis (RO) plants

General high-pressure services in oil & gas and chemical sectors

Additional Features

Replaceable wear parts reduce downtime and maintenance cost

Compact and robust design ideal for tight installation spaces

Flexible nozzle orientations and baseplate options

High mechanical integrity to withstand thermal expansion

Optional instrumentation for advanced monitoring and control

The Sulzer MD pump combines rugged reliability with refined performance for your most demanding high-pressure services. With its ring-section multistage configuration and engineered efficiency , it delivers optimal flow , extended run times , and peace of mind. When uptime and energy savings are critical , the MD pump stands strong.