Description

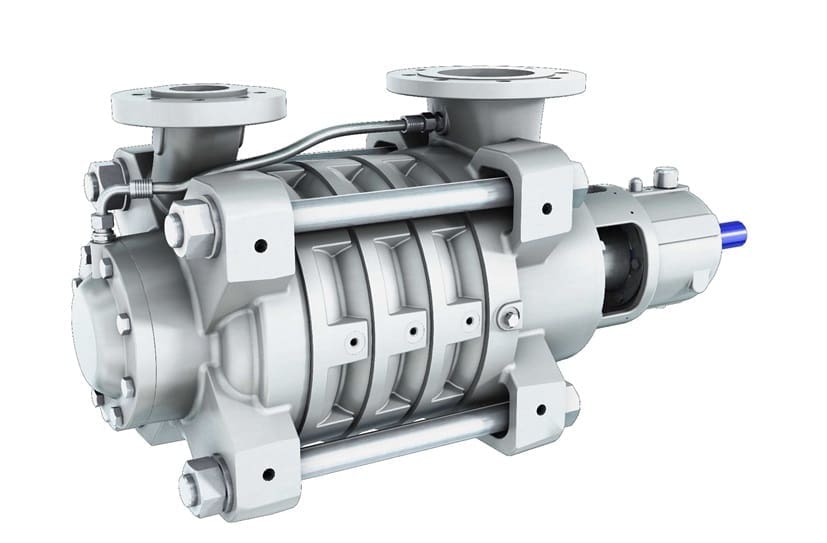

Sulzer Centrifugal Between bearing pumps MBN high-pressure stage casing pumps -Multi-purpose solutions for all high-pressure needs

Key Technical Specifications:

| Capacities | Up to 700 m3/h / 3,080 US gpm |

| Heads | Up to 900 m / 2,950 ft |

| Pressures | Up to 100 bar / 1,450 psi |

| Temperatures | Up to 180°C / 355°F |

| Discharge sizes | Up to 150 mm / 6 inches |

Why Choose Sulzer MBN High-Pressure Stage Casing Pumps?

The Sulzer MBN pump series is built for demanding high-pressure applications that require robust construction , efficient performance , and long operating life. With a ring-section design and radial split casing , the MBN excels in flexible multi-stage operation , making it ideal for power generation , desalination , and industrial water systems. Compact , efficient , and engineered to API 610 or ISO 5199 standards , it’s a versatile solution where reliability matters most.

Key Technical Specifications

Pump Type: Multistage centrifugal pump , between bearings

Design: Radially split , ring-section casing with horizontal or vertical installation

Impeller: Enclosed radial impellers , dynamically balanced

Seal Options: Single or double mechanical seals , API plans available

Bearings: Grease or oil-lubricated antifriction or sleeve bearings

Design & Functionality

Modular stage design enables tailored hydraulic coverage and optimized head per stage

Axial thrust is balanced by opposed impeller arrangement or balance disc

Rigid rotor with low vibration and high stability during transient loads

Compact horizontal or vertical execution for space-constrained installations

Service-friendly design allows quick disassembly for inspection and overhaul

Typical Applications

Boiler feedwater for industrial or small-scale power plants

Reverse osmosis (RO) systems in desalination plants

High-pressure water supply for irrigation or process industries

Condensate extraction and transfer duties in thermal cycles

General high-pressure utility services in refineries and chemical plants

Additional Features

Hydraulic efficiency optimized with CFD design and test-validated performance

Optional instrumentation ports for temperature and pressure monitoring

Balance device options for high-pressure axial thrust compensation

Sealing configurations for hazardous or environmentally sensitive fluids

Available in multiple metallurgies including stainless steel , duplex , or super duplex