Description

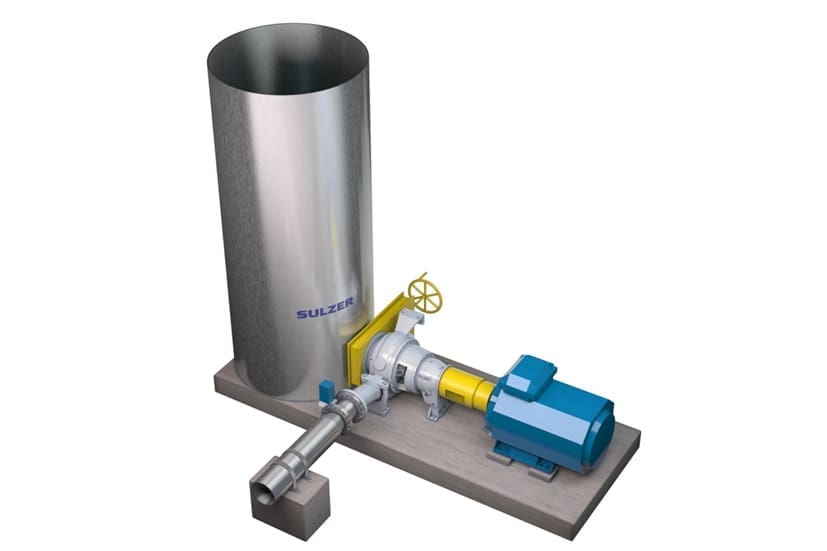

Sulzer Medium-consistency products KCE™ medium-consistency pumping system -The most advanced technology for semi-medium consistency pumping

Key Technical Specifications:

| Capacities | Up to 850 l/s / 13’500 US gpm |

| Heads | Up to 85 m / 280 ft. |

| Pressures | Up to 25 bar / 360 psi |

| Temperatures | Up to 180 °C / 355 °F |

| Discharge sizes | from 150 mm 350 mm / 6-14 in |

| Maximum speed of rotation | Up to 1 500 r/min |

| Performance range | KCE™ medium-consistency centrifugal pumps have wide hydraulic coverage to satisfy the most demanding requirements of semi-medium consistency (intermediate consistency) fibrous slurry applications. |

Why Choose Sulzer KCE™ Medium-Consistency Pumping System?

The Sulzer KCE™ is engineered for efficient , reliable pumping of medium-consistency pulp , offering high operational stability , low energy consumption , and exceptional wear resistance. Its design ensures smooth handling of fiber suspensions in demanding pulp and paper processes.

Key Technical Specifications

Design: Single – stage centrifugal pump for medium – consistency applications

Capacity Range: Optimized for pulp consistencies of 8 – 16%

Impeller: Specially contoured to handle fiber-rich slurries efficiently

Seal Options: Mechanical seals designed for pulp suspension duties

Drive Power: Configured to match specific process requirements

Operating Limits

Medium: Fiber suspensions with medium consistency

Consistency Range: 8% to 16%

Temperature: Suitable for typical process temperature ranges

Operation: Continuous-duty performance in critical process lines

Typical Applications

Stock preparation and approach flow systems

Bleaching and washing stages

Screening and cleaning processes

Pulp and paper mill production lines

Additional Features

Optimized hydraulics for high efficiency and low operating costs

Rugged construction for long service life in abrasive media

Stable flow with minimal pulsations and vibrations

Easy integration into existing piping systems

Self-venting capability to prevent air lock