Description

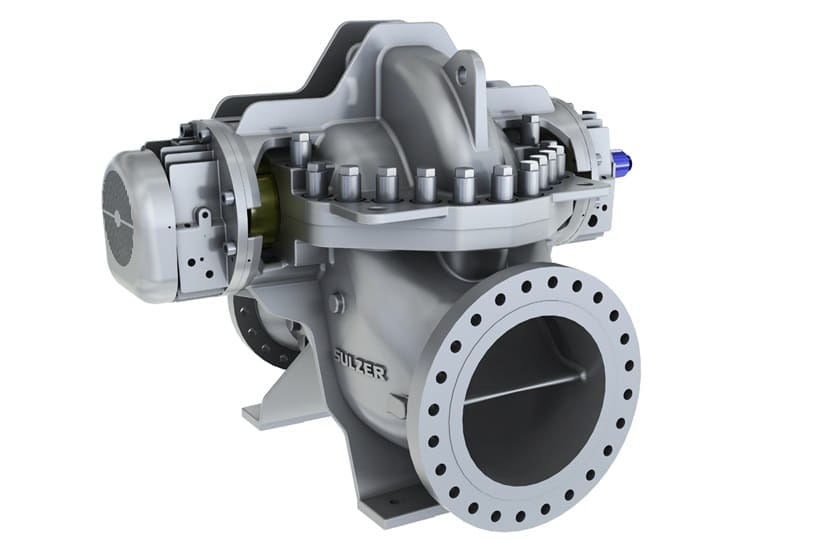

Sulzer Centrifugal Between bearing pumps HSA axially split single stage between bearing pump – Reliability and efficiency for critical services

Key Technical Specifications:

| Capacities | Up to 18000 m3/h / 80000 US gpm |

| Heads | Up to 260 m / 850 ft |

| Pressures | Up to 34 bar / 490 psi |

| Temperatures | Up to 150°C / 300°F |

| Discharge sizes | 150 to 800 mm / 6 to 32 inches |

| Maximum speed of rotation | Up to 3600 rpm |

Why Choose Sulzer HSA Axially Split Pump?

The Sulzer HSA pump is a robust , high-capacity , between-bearing , axially split , single-stage centrifugal pump designed for critical applications in power generation , water transport , oil & gas , and general industry. Its double-suction impeller and horizontal split casing ensure excellent hydraulic stability , high efficiency , and ease of maintenance. Engineered to meet the most demanding operational requirements , the HSA is a proven performer for both clean and slightly contaminated fluids.

Key Technical Specifications

Pump Type: Between-bearings , axially split , single-stage centrifugal pump

Casing Design: Horizontally split volute casing for easy internal access

Impeller: Double-suction , enclosed , dynamically balanced

Standards Compliance: ISO 13709 / API 610 (BB1 configuration)

Materials of Construction:

– Casing: Cast steel , ductile iron , or stainless steel

– Impeller: Bronze , stainless steel , or duplex

– Shaft: High-strength steel or stainless steel

Bearings: Sleeve or rolling element bearings; oil-lubricated or forced lubrication systems

Seal Options: Single , double mechanical seals or API Plan options

Design & Functionality

Axial split design simplifies inspection and reduces service time

Double-suction impeller design for low NPSH and hydraulic balance

Rigid construction minimizes vibration , supports long MTBF

Low radial and axial loads reduce wear on mechanical components

Optional cooling/heating jackets available for thermal control

Typical Applications

Circulating water systems in thermal and nuclear power plants

Crude oil and refined product pipeline pumping

Water injection and cooling systems

Large-scale irrigation and water transport

Industrial fluid transfer in refineries and process plants

Additional Features

Fully compliant with API 610 (BB1) for critical industrial and energy sectors

Maintenance-friendly split casing allows quick seal and bearing access

Double-suction design handles high flow rates with low vibration

Broad range of materials and seal configurations for corrosive/abrasive services

Customizable mounting and baseplate options for plant integration

The Sulzer HSA is a heavy-duty , axially split , between-bearing centrifugal pump designed for continuous performance in the world’s most demanding flow and pressure applications. With unmatched hydraulic stability , low vibration operation , and superior serviceability , it delivers long-term reliability for critical infrastructure across the power , water , and process industries.