Description

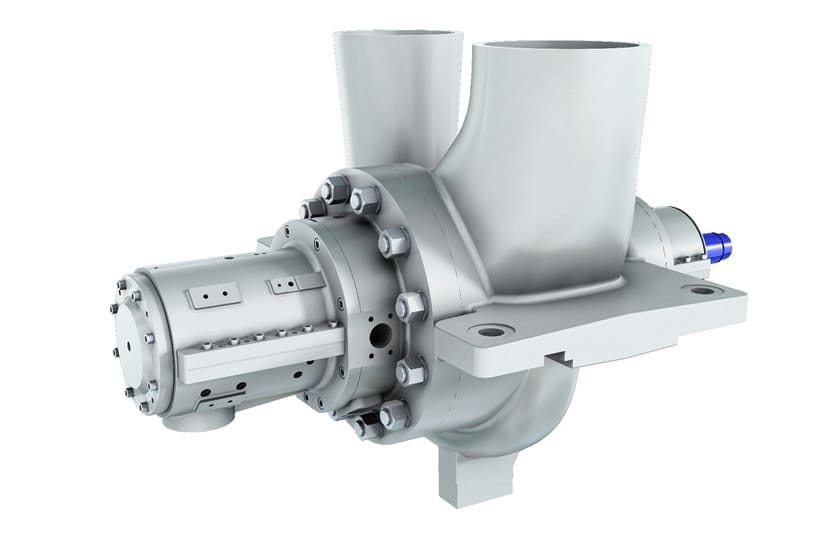

Sulzer Centrifugal Between bearing pumps HPTd single stage double suction pump -A neat design for nuclear / single stage double suction pumps stand the test of time

Key Technical Specifications:

| Capacities | Up to 5,000 m3/h / 22,000 US gpm |

| Heads | Up to 800 m / 2,625 ft |

| Pressures | Up to 150 bar / 2,175 psi |

| Temperatures | Up to 220°C / 428°F |

| Discharge sizes | Up to 450 mm / 18 inches |

Why Choose Sulzer HPTd Single Stage Double Suction Pump?

The Sulzer HPTd pump is designed for high-efficiency , heavy-duty applications requiring robust hydraulic performance and low maintenance. Featuring a single-stage , axially split casing with a double-suction impeller , the HPTd combines high capacity with stable , vibration-free operation. It’s ideal for critical utility and process applications in power generation , desalination , and water transport systems.

Key Technical Specifications

Pump Type: Between-bearings , axially split , single-stage centrifugal pump

Impeller Type: Double-suction closed impeller

Casing Design: Horizontally split for easy maintenance and rotor access

Standards Compliance: API 610 , ISO 13709 , or custom industrial standards

Materials of Construction:

– Casing: Carbon steel , ductile iron , or stainless steel

– Impeller: Bronze , stainless steel , or duplex steel

– Shaft: High-strength alloy steel

Bearings: Sleeve or rolling element bearings with options for forced lubrication

Sealing: Mechanical seals per API plans or gland packing options

Design & Functionality

Double-suction impeller provides balanced hydraulic loads and high flow efficiency

Axially split design allows easy inspection and overhaul without disturbing piping

Designed for low vibration and quiet operation in large flow systems

Configurable suction and discharge orientations

Shaft design optimized for deflection control and long seal life

Compatible with electric motors or turbine drives

Typical Applications

Boiler feed systems and condensate extraction in power plants

Water transmission in irrigation or municipal systems

Circulating pumps for district heating and cooling networks

Desalination plant intake and product water pumping

Industrial process cooling and large-scale fluid transfer

Additional Features

Symmetrical casing for uniform thermal expansion

High-efficiency hydraulics minimize energy consumption

Low NPSH requirements ensure cavitation-free operation

Optional condition monitoring ports and seal support systems

Field-serviceable design supports reduced downtime