Description

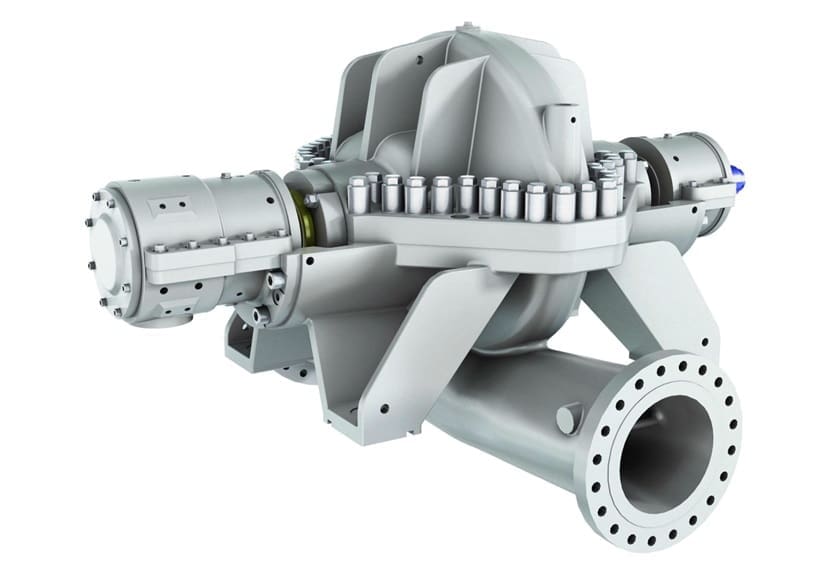

Sulzer Centrifugal Between bearing pumps HPDM axially split volute casing pump -Tailor-made water and oil transportation pumps.

Key Technical Specifications:

| Capacities | 1,000 to 20,000 m3/h / 4,400 to 88,000 US gpm |

| Heads | Up to 700 m / 2,300 ft |

| Pressures | Up to 175 bar / 2,500 psi |

| Temperatures | Up to 70ºC / 160ºF |

| Discharge sizes | 250 to 1,600 mm / 10 to 64 inches |

Why Choose Sulzer HPDM Axially Split Pump?

The Sulzer HPDM is a high-performance , between-bearing , axially split volute casing pump engineered for demanding applications requiring high flow rates , high pressures , and robust reliability. Its double-suction impeller and symmetrical casing design ensure excellent hydraulic balance , reduced vibration , and extended service life. Ideal for both clean and slightly contaminated fluids , the HPDM excels in power , water , and industrial process applications where uptime and performance are critical.

Key Technical Specifications

Pump Type: Between-bearings , axially split , single-stage centrifugal pump

Casing Design: Horizontal split volute casing for easy access and maintenance

Impeller: Double-suction , dynamically balanced , enclosed design

Materials of Construction:

– Casing: Carbon steel, ductile iron , stainless steel , or duplex

– Impeller: Bronze , stainless steel , duplex

– Shaft: High-strength stainless steel

Bearings: Sleeve or antifriction bearings with forced or oil bath lubrication

Seal Type: Single or double mechanical seals; API seal plans available

Design & Functionality

Axially split casing simplifies inspection and service without disturbing piping or motor

Double-suction impeller minimizes axial thrust and provides hydraulic stability

Precision-machined internals reduce losses and enhance efficiency

Available with cooling and heating jackets for temperature control

Can be adapted with baseplates , dampers , or API-compliant systems

Typical Applications

Power generation: boiler feedwater , condensate extraction

Water transport: high-pressure water transfer , irrigation

Refinery and petrochemical process services

District heating and cooling

Desalination and large-scale cooling water systems

Additional Features

Back-to-back impeller design reduces axial load and bearing wear

Optional cartridge-style mechanical seals for easy replacement

Rigid baseplate minimizes vibration for smoother operation

Designed per ISO 13709 / API 610 (BB1 type) standards

Proven performance with custom materials and hydraulic configurations