Description

Sulzer Centrifugal Between bearing pumps GSG low flow pump -The reliable API 610 solution for low flow services

Key Technical Specifications:

| Capacities | Up to 35 m3/h / 155 US gpm |

| Heads | Up to 1’800 m / 5’900 ft |

| Pressures | Up to 200 bar / 2’900 psi |

| Temperatures | From -29 °C to +200 °C / -20 °F to +400 °F |

| Flange ratings | 600#, 900#, 1500# and 2500# |

| Maximum speed of rotation | Up to 3’600 rpm |

Why Choose Sulzer GSG Low Flow Pump?

The Sulzer GSG Low Flow pump is a specialized version of the trusted GSG barrel pump , engineered specifically for high-pressure applications where flow rates are minimal but reliability is critical. Designed to handle harsh process conditions and precise system demands , it offers exceptional hydraulic stability , thermal control, and safety in compact , low-flow service environments-making it ideal for refinery and chemical processes that operate under tight performance windows.

Key Technical Specifications

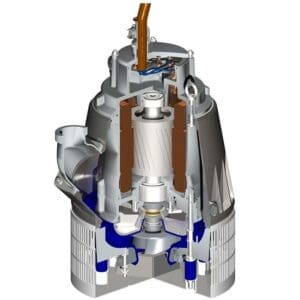

Pump Type: Between-bearings , multistage , radially split barrel pump (BB5)

Flow Range: Optimized for low flow ; typically < 50 m³/h

Casing Design: Barrel-type casing with diffuser-style hydraulics

Standards: Fully compliant with API 610 (BB5) , ISO 13709

Materials:

– Casing: Forged alloy steel or stainless steel

– Impellers/Diffusers: High-grade stainless or duplex steel

Shaft Bearings: Sleeve and tilting pad thrust bearings with forced lubrication

Sealing System: API 682 mechanical seals with Plan 53 or 54 options

Design & Functionality

Multistage diffuser-style design ensures low NPSH requirements and excellent efficiency

Barrel casing construction handles extreme pressure safely and minimizes vibration

Customized hydraulic design tailored to low flow, high head performance

Optional balance drum for axial thrust management

Modular rotor and cartridge assembly simplifies maintenance

Adaptable nozzles and mounting orientations for integration in complex layouts

Typical Applications

High-pressure boiler feedwater systems with limited flow demand

Hydroprocessing and catalytic reforming units in refineries

Chemical injection or sampling in petrochemical processes

Condensate service in compact high-temperature systems

Water or solvent transfer in pressurized low-capacity loops

Additional Features

Excellent hydraulic control at low flow to avoid recirculation and wear

High-efficiency internals reduce energy consumption even under minimal load

Long life with low vibration and axial thrust balancing

API 610 and API 682 ready with full auxiliary sealing systems

Compact footprint with vertical and horizontal installation flexibility

Built for precision, the Sulzer GSG Low Flow pump is a high-pressure solution that thrives where most pumps struggle. With robust construction, tight hydraulic control, and barrel-style safety, it delivers reliable performance for demanding low-flow, high-head applications in critical energy and process systems. When the margin for error is zero, GSG Low Flow delivers.