Description

Sulzer Separation technology Random packings Conventional random packings -Wide portfolio of rings for your needs

Nutter Ring™

High-performance random packing designed by Dale Nutter in 1984

Efficiency is enhanced by lateral liquid spreading and surface film renewal

Superior surface utilization allows for shorter packed beds

Extensively tested by the Fractionation Research Institute (FRI), making the Nutter Ring one of the best known high-performance random packings

Geometry provides maximum randomness with minimum nesting and maximum mechanical strength

I-Ring™

Equivalent to the Intalox Metal Tower Packing (IMTP), the industry‘s first and most widely used high-performance random packing introduced in the late 1970’s

Geometry ensures low liquid hold-up and a significant improvement in capacity compared to Pall rings

C-Ring™

Equivalent to the widely used Cascade Mini-Ring (CMR)

Evolution of Pall ring employing a much lower diameter-to-height ratio favoring orientation that results in lower pressure drop and higher capacity

Excellent mechanical strength

C-rings excel within random packing in fouling media

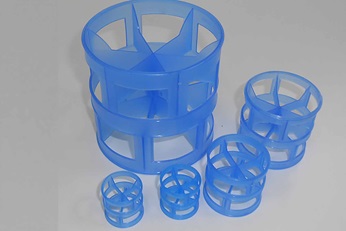

Plastic C-Ring™

Equivalent to the Plastic Cascade Mini Ring (CMR)

Better capacity & efficiency than Pall Ring with low aspect ratio of 1:3 (height/diameter)

Lower pressure drop

Available in PP, PVC/C, PE, PVDF, ETFE, PFA

P-Ring™

Equivalent to the widely used Pall ring

Designed by BASF AG around 1940 based on the Raschig ring

Punched “shovels” leave “windows” on the outside, facilitating vapor flow and increasing capacity compared with the R-Ring

Extensively tested by research institutes worldwide

Plastic P-Ring™

Equivalent to Plastic Pall Ring

The most common plastic random packing type used in industry

Available in PP, PVC/C, PE, PVDF, ETFE, PFA

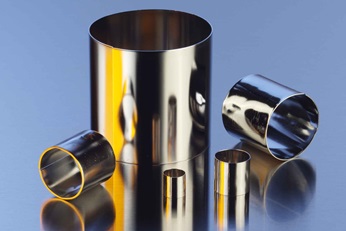

R-Ring™

Equivalent to the widely used Raschig ring

Employing a diameter-to-height ratio of ~1 makes the Raschig ring the first “designed” random packing, introduced by Fritz Raschig at the end of the 19th century

S-RingTM

100% equivalence to Raschig Super-Ring, a well introduced ring type in the petrochemical industry

One of the first so called high-performance rings

Well established in a number of licensed process technologies

Alternating wave structure prevents entanglement of individual pieces

Why Choose Conventional Random Packings?

Sulzer’s conventional random packings are a proven solution for reliable mass transfer performance in a wide range of applications. Designed with simple yet effective geometries , they offer balanced efficiency , mechanical strength , and cost-effectiveness. Their robust design ensures long service life , while the broad material selection allows customization to meet specific process and chemical resistance needs.

Typical Applications

Distillation and absorption processes

Gas scrubbing and stripping operations

Heat recovery and chemical processing

Refining and petrochemical plants

Additional Features

Established , time-tested packing designs

Moderate pressure drop with stable performance

High mechanical strength for various operating conditions

Available in multiple sizes and materials for process flexibility

Sulzer Conventional Random Packings — the dependable choice for versatile , efficient , and cost-effective separation solutions.