Description

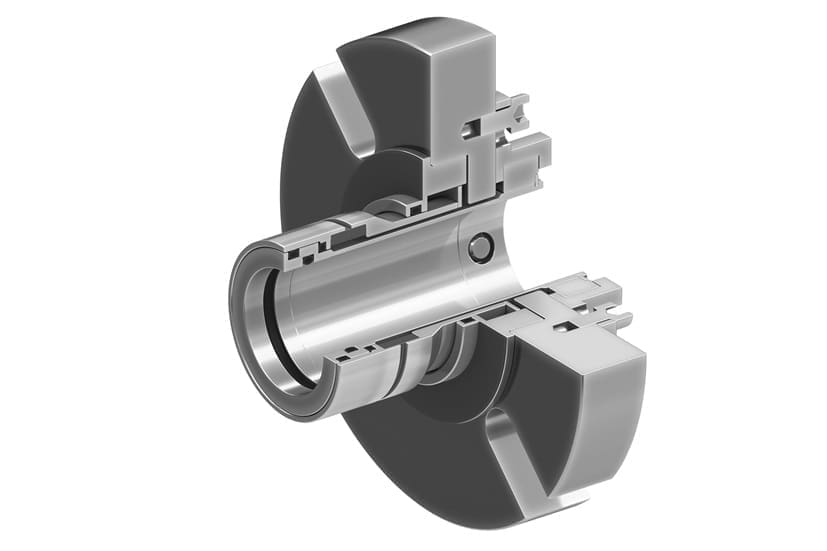

Sulzer Mechanical seals and accessories Cartridge seals -TS mechanical seals for reliable operation and fast and easy maintenance

Key Technical Specifications:

| TS1 | TS1 with Flushing | TS2/TS2P | |

| P max | 25 bar / 363 psi | 25 bar / 363 psi | 25 bar / 363 psi |

| V max | 25 m/s / 82 ft/s | 25 m/s / 82 ft/s | 25 m/s / 82 ft/s |

| T max | 125°C / 257°F | 140°C / 284°F with internal flushing140°C / 284°F with external flushing |

180°C / 355°F |

| Seal faces |

SiC/SiC, C/SiC | SiC/SiC, C/SiC | SiC/SiC-SiC/SiC SiC/SiC-C/SiC |

| O-rings |

EPDM, FKM | EPDM, FKM | EPDM, FKM |

| Wetted parts |

316 stainless steel (EN 1.4401, EN 1.4436), duplex EN 1.4462, super duplex EN 1.4410 |

316 stainless steel (EN 1.4401, EN 1.4436), duplex EN 1.4462, super duplex EN 1.4410 |

316 stainless steel (EN 1.4401, EN 1.4436), duplex EN 1.4462, super duplex EN 1.4410 |

Why Choose Sulzer Cartridge Mechanical Seals?

Sulzer Cartridge Seals are fully pre-assembled sealing units designed for fast installation , precise alignment , and consistent performance. By integrating all seal components into a single cartridge , they eliminate the need for complex setting measurements and reduce the risk of installation errors. Ideal for demanding industrial applications , these seals are built to handle high pressures , variable temperatures , and aggressive media while minimizing maintenance downtime.

Key Technical Specifications

Seal Format: Complete cartridge-type mechanical seal for simplified installation

Design: Balanced configuration to reduce face load and heat generation under high pressure

Materials & Build:

Seal faces in silicon carbide , tungsten carbide , or carbon graphite to suit application media

Elastomers available in Viton , EPDM , or FFKM for optimal chemical resistance

Metallic components in stainless steel or high-alloy grades for corrosion resistance

Spring Arrangement: Isolated springs to prevent clogging from solids or viscous fluids

Installation Features: No measurement or axial setting required; supplied with installation clips or spacers for correct positioning

Operating Limits

Shaft Diameter: Typically 25 mm – 150 mm (model dependent)

Pressure Rating: up to 30 bar(g) depending on seal type

Speed: up to 25 m/s

Temperature Range: –20 °C to +200 °C (material dependent)

Typical Applications

Sulzer process and industrial pumps in chemical , petrochemical , and refinery services

Cooling water and circulation pumps in power generation

Slurry and abrasive media handling with hard face combinations

Pumps in water treatment , pulp and paper , and food processing where clean sealing is critical

Additional Features

Pre-set working length ensures repeatable installation accuracy

Cartridge design reduces downtime during seal replacement

Suitable for single , double , or tandem arrangements for varying duty conditions

Can be supplied with integrated flushing , quench , or pressurized barrier systems

Balanced design tolerates pressure reversals and high vibration environments