Description

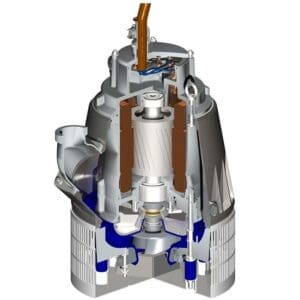

Valmet Flow control Ball valves Neles™ modular ball valve, series M -Ball valve optimized for variaty of pulp and paper applications

Key Technical Specifications:

| Construction | Flanged, seat supported & trunnion mounted, full bore ball valve |

| Size range | DN 25 – 600/NPS 1”–24” (M1-series) |

| DN 25 – 600/NPS 1”–24” (M2-series) | |

| DN 100 – 400/NPS 4”–16” (M9-series) | |

| Face to face | M1: ISO 5752 |

| M2: ASME B16.10 | |

| M9: Old Neles series P (internal) | |

| Pressure ratings | EN PN 10-40, ASME 150-300, JIS 10K-20K |

| Temperature range | -50 °C … +260 °C / -60 °F … +500 °F |

Why choose Neles™ modular ball valve , series M?

They offer a versatile and durable solution for a wide range of process applications , combining reliable tight shutoff , efficient flow control , and long-lasting performance. The modular design allows flexible configuration , easy adaptation to specific needs , and simplified maintenance.

Typical applications

Oil and gas production , processing , and transmission

Petrochemical and chemical plants

Power generation and utilities

Pulp and paper industry

General industrial flow control

Additional features

Seat-supported design for robust sealing performance

Modular construction for easy customization and maintenance

Trunnion or floating ball configurations available

Wide range of materials , trims , and end connections

High cycle life and low operating torque

Suitable for both on/off and control applications