Description

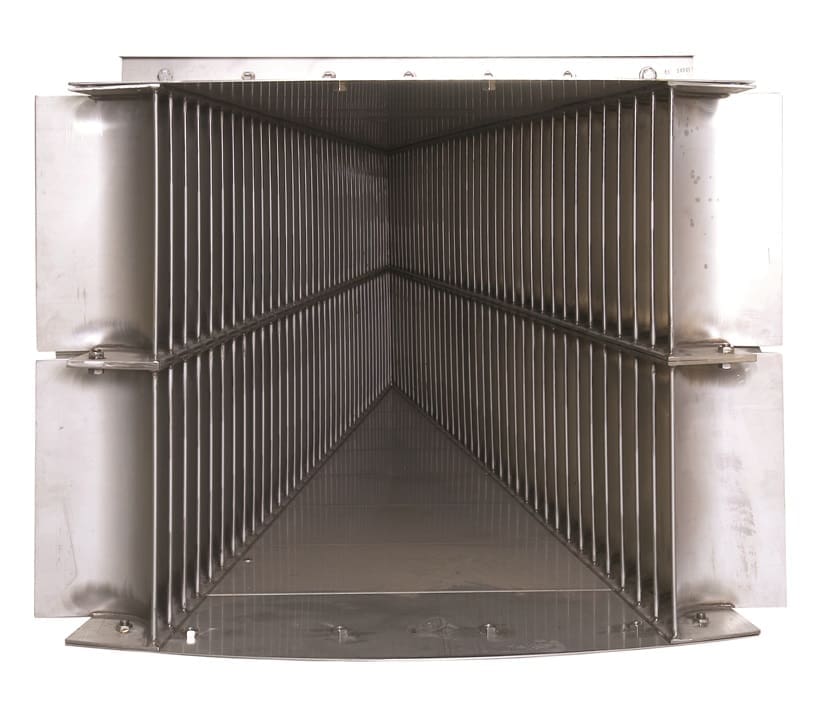

Sulzer Separation technology Feed inlet devices Shell Schoepentoeter™ and Schoepentoeter™ Plus -Uniform separation with the Shell Schoepentoeter inlet device

Technology

The purpose of a Schoepentoeter™ and Schoepentoeter™ Plus is to decrease the momentum of the feed , perform a first stage separation of solids and liquid from the vapor , and achieve an even vapor distribution across the vessel cross section. This is obtained by splitting the feed mixture into a series of flat jets.

Why Choose Shell Schoepentoeter™ and Schoepentoeter™ Plus?

The Shell Schoepentoeter™ and Schoepentoeter™ Plus inlet devices are engineered to optimize gas–liquid separation by providing uniform flow distribution and minimizing entrainment at the column inlet. Their advanced design reduces turbulence , enhances separation efficiency, and supports higher operational throughput. The Plus version offers improved performance for challenging process conditions , ensuring reliability and long-term operation.

Typical Applications

Gas–liquid separation in distillation, absorption, and stripping columns

Inlet conditioning for oil & gas production facilities

Processing plants requiring high-capacity separation

Debottlenecking upgrades for existing units

Additional Features

High separation efficiency with minimal pressure drop

Uniform phase distribution to protect downstream internals

Available in multiple sizes and materials for various process conditions

Proven design with a long track record in the industry