Description

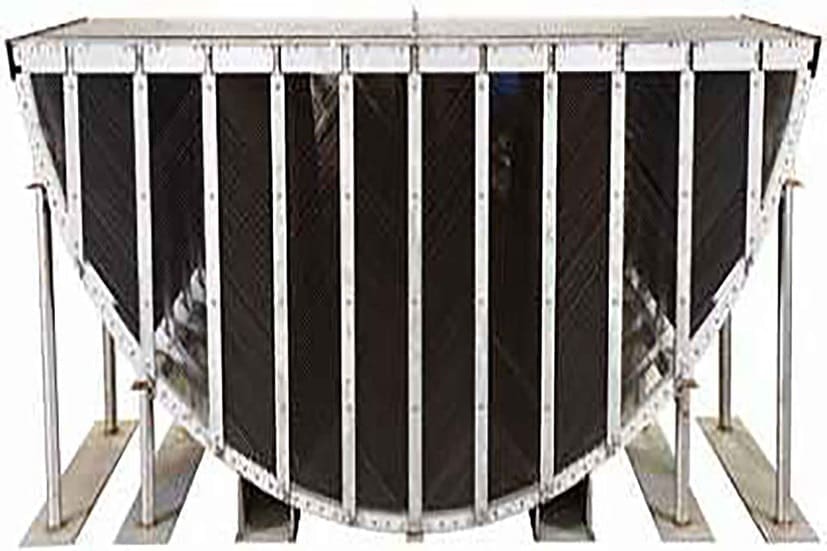

Sulzer Separation technology Coalescers Mellaplate™ coalescer -Sulzer equipment enhances the coalescence process

Key Technical Specifications:

| Mellaplate W | Mellaplate MG | Mellaplate M | Mellaplate N | |

| Construction form | Flat parallel plates | Structured corrugated flat plates | Structured corrugated metal sheets | Structured corrugated plastic sheets |

| Relative capacity | 1 | 1.5 | 1.5 | 1.5 |

| Typical droplet cut-off size |

≥ 50 μm | ≥ 100 μm | ≥ 50 μm | ≥ 50 μm |

| Pressure drop | Negligible | 0.5 – 4 mbar | 1 – 10 mbar | 1.5 – 15 mbar |

| Solids handling | High fouling resistance | Good to high fouling resistance | Moderate to good fouling resistance | Moderate to good fouling resistance |

| Remarks | Also used as wave and foam breaker elements | More suited for de-oiling due to the plastic surface |

Why Choose Mellaplate™ Coalescer?

Mellaplate™ Coalescers offer superior performance in separating immiscible liquid phases , combining high efficiency with low operating costs. Their unique plate design maximizes coalescence area , ensuring rapid droplet growth and separation even under challenging flow conditions. Ideal for applications requiring precise liquid–liquid separation , they help improve process stability and product purity.

Typical Applications

Oil – water separation in refineries and petrochemical plants

Produced water treatment in offshore and onshore facilities

Separation of immiscible liquids in chemical processing

Wastewater treatment for industrial plants

Additional Features

Optimized plate geometry for enhanced separation efficiency

Compact, modular design for easy installation and retrofitting

High corrosion resistance for aggressive process environments

Low pressure drop for reduced energy consumption