Description

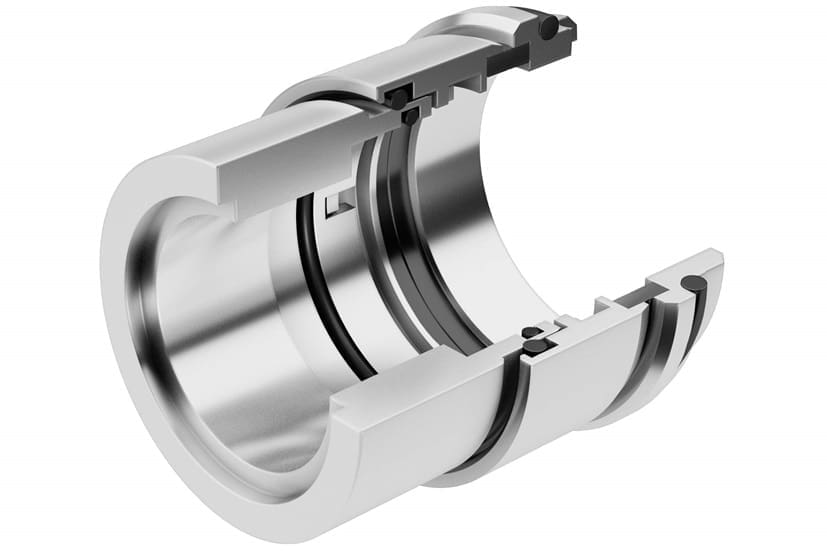

Sulzer Mechanical seals and accessories Element seals -Optimal seal solution for AHLSTAR pumps

Key Technical Specifications:

| SI units | US units | |

| Pmax | 16 bar | 232 psi |

| Vmax | 10 m/s | 33 ft/s |

| Tmax | 140°C | 284°F |

| Seal surface | SiC/SiC | SiC/SiC |

| O-ring | EPDM or FKM | EPDM or FKM |

| Material | 316 Stainless Steel (EN 1.4401, EN 1.4436) or Duplex EN 1.4462 | 316 Stainless Steel (EN 1.4401, EN 1.4436) or Duplex EN 1.4462 |

Why Choose Sulzer Element Mechanical Seals?

Sulzer Element Seals provide a flexible , service-friendly sealing solution where only the worn sealing elements are replaced instead of the entire seal assembly. This approach reduces spare parts cost , minimizes waste , and shortens maintenance time while preserving the existing seal housing and hardware. Designed to fit seamlessly into Sulzer pumps , element seals maintain the original performance and reliability while offering cost-effective lifecycle management.

Key Technical Specifications

Seal Format: Replacement element kit for in-situ refurbishment of mechanical seals

Design Principle: Maintains existing gland and sleeve while replacing core sealing faces, springs, and secondary seals

Materials & Options:

Seal faces in silicon carbide , tungsten carbide , or carbon graphite for optimal wear resistance

Elastomer options (Viton , EPDM , FFKM) for compatibility with a wide range of fluids

Springs and metal parts in stainless steel or high-alloy grades for durability

Precision Fit: Machined to exact tolerances to ensure alignment with the existing seal hardware

Ease of Assembly: Supplied with all necessary components for straightforward on-site replacement

Operating Limits

Shaft Diameter: Matches the original seal configuration (typically 25 mm – 150 mm)

Pressure Rating: up to 25 bar(g) depending on seal design

Speed: up to 25 m/s

Temperature Range: –20 °C to +200 °C (material dependent)

Typical Applications

Sulzer centrifugal and process pumps where the seal housing and hardware remain in serviceable condition

Industrial plants aiming to reduce total sealing costs and downtime

Chemical , petrochemical , and water industry applications with predictable maintenance cycles

Situations where rapid seal refurbishment is preferred over full seal replacement

Additional Features

Cost-effective maintenance solution—replace only the sealing elements , not the full unit

Reduces environmental impact by minimizing waste from discarded hardware

Maintains original performance and reliability of the pump’s sealing system

Compatible with single , double , and cartridge-type seal configurations

Factory-quality components ensure restored sealing efficiency