Description

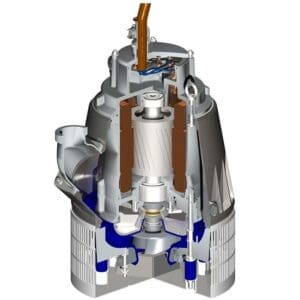

Sulzer Centrifugal Submersible dewatering pumps Submersible drainage pump XJ 80 -Engineered to save costs

Key Technical Specifications:

50HZ

| Electric submersible pump | XJ 80 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 7.5 x 22 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 8.3 kW |

| Speed | 2,920 rpm |

| Power cable | 20 m type H07RN8-F |

60HZ

| Electric submersible pump | XJ 80 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 7.5 x 22 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 9.8 kW |

| Speed | 3,520 rpm |

| Power cable | 20 m type H07RN8-F |

The XJ 80 is engineered for challenging dewatering tasks in construction , tunneling , mining , stormwater pits , and similar environments:

Built for pumping dirty water with light abrasive content under demanding conditions.

Available with AquaTronic electronic control (built-in or optional) , ensuring correct impeller rotation despite phase connection order , and providing integrated protection against overload , missing phase , overheating, dry-running , and clogging.

Plug‑and‑pump design: install directly without external control panels. Diagnostics and pump status can be accessed via USB without disassembly.

Robust modular construction simplifies maintenance and minimizes downtime with low spare parts stocking.

Technical Specifications

Motor & Performance

50 Hz: 8.3 kW motor , up to ~52 L/s flow and ~76 m head

60 Hz: 9.8 kW (≈ 13 hp) , up to ~37 L/s flow and ~94 m head (~308 ft)

Protection & Durability

Weight: ~63 kg for ND/LD/HD variants; ~78 kg for SD model (without cable)

Maximum submergence: ~20 m (65 ft); protection class: IP 68

Max pumped-fluid temperature: up to ~40 °C (104 °F) in continuous duty

Max fluid density: ~1100 kg/m³; pH range: 5–8

Solids passage: strainer holes ~7.5 × 22 mm (5/16″ × 7/8″)

Start cycles/hour: up to 30

Feature Options & Variants

Model variants:

‑ XJ 80 ND (medium-head)

‑ XJ 80 LD (high-flow)

‑ XJ 80 HD (high-head, 60 Hz only)

‑ XJ 80 SD (super high-head)

AquaTronic (AT) version includes electronics for automatic phase correction, integrated DOL or soft-start, motor protection, anti‑clog, and diagnostics logged via USB.

Level control options (with AquaPlug or level-sensor combo) enable automated dry-run protection, energy-saving level-based stop/start, and system alarms.

Discharge options: hose connections in 3″, 4″, or 6″; threaded BSP/NPT or Storz couplings available.

Accessories: flotation rings, zinc anode corrosion protection, service data kits, protective coatings.

Construction materials: aluminum casing , stainless steel shaft and fasteners , white cast-iron impeller, nitrile rubber wear parts; dual mechanical seals in oil bath.