Description

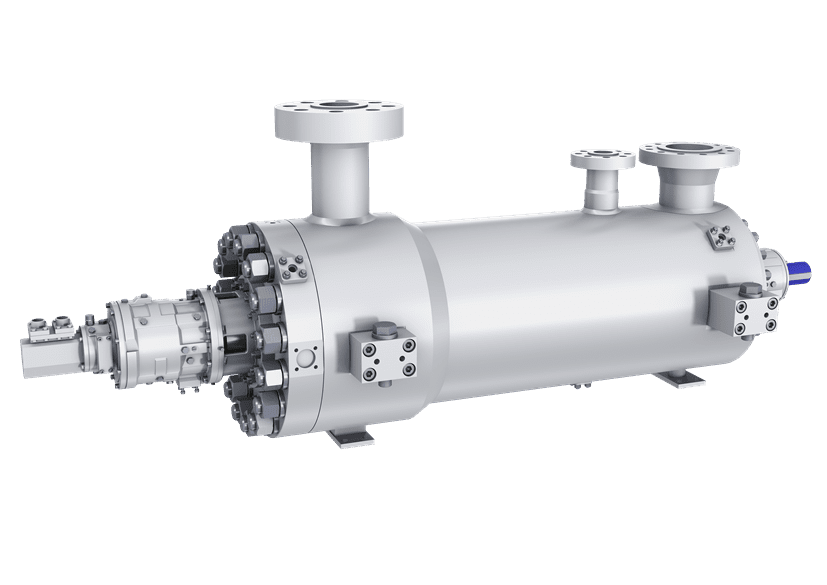

Sulzer Centrifugal Between bearing pumps GSG-BFP diffuser style barrel pump for feedwater applications -The competitive choice for feedwater applications

Key Technical Specifications:

| Capacities | up to 1’000 m3/h / 5’300 US gpm |

| Heads | up to 2’800 m / 10’500 ft |

| Discharge sizes | up to 250 mm / 10 in |

| Discharge pressures | up to 350 bar / 5’080 psi |

| Suction pressures | up to 65 bar / 940 psi |

| Temperatures | up to 210ºC / 410ºF (higher temperatures upon request) |

Why Choose Sulzer GSG-BFP Diffuser Style Barrel Pump?

The Sulzer GSG-BFP is purpose-built for demanding boiler feedwater applications , offering high reliability , precise performance , and superior pressure handling. As a radially split , multistage barrel pump with diffuser design , it meets and exceeds API 610 (BB5) standards. It is the ideal solution for power plants and industrial installations where continuous duty and high-pressure performance are critical.

Key Technical Specifications

Pump Type: Multistage , diffuser style barrel pump (API 610 BB5)

Casing: High-strength forged barrel construction for extreme pressure applications

Hydraulics: Precision-cast impellers and diffusers for high head and efficiency

Design Standards: API 610 , ISO 13709 compliant

Sealing System: Double mechanical seals with API Plan 52 , 53 , or 54 options

Bearings: Pressure-lubricated sleeve and tilting-pad bearings

Design & Functionality

Radial split, centerline-mounted barrel casing handles thermal expansion effectively

Optimized diffuser design ensures smooth flow , high efficiency , and reduced vibration

Internally staged to handle high head per stage while minimizing axial thrust

Cartridge-type rotor allows for easy maintenance without disturbing pipework

Advanced thrust balancing system ensures stable , long-lasting operation

Typical Applications

Boiler feedwater systems in thermal , nuclear , and combined-cycle power plants

High-pressure feed pumping in industrial steam generation

Water injection and pressurized feed systems in refining and chemical plants

Continuous-duty, high-head applications requiring low downtime and extended runtime

Additional Features

Forged barrel casing design for maximum safety and mechanical integrity

Designed for long-term service intervals and reduced total cost of ownership

Internally staged layout with precision balancing reduces wear and increases efficiency

Optional condition monitoring sensors for predictive maintenance

Field-proven reliability in both base-load and cycling plant operations