Description

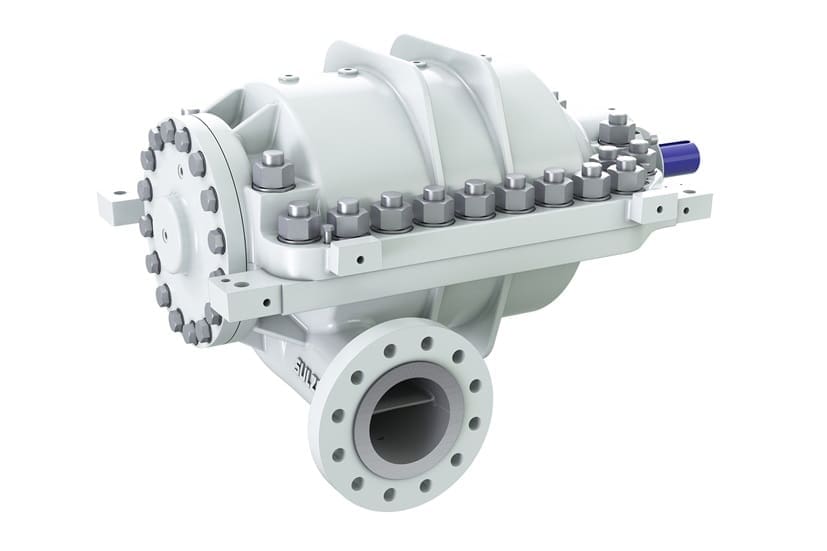

Sulzer Centrifugal Between bearing pumps MSN-RO axial split multistage membrane feed pump -Deliver optimum performance in a challenging environment

Key Technical Specifications:

| Capacities | Up to 1’450 m3/h / up to 7’680 USgpm |

| Heads | Up to 840 m / 2’940 ft. |

| Pressures | Up to 100 bar / 1’450 psi |

| Temperatures | Up to 50ºC / 122ºF |

| Discharge sizes | Up to 200 mm / up to 8 in. |

Why Choose Sulzer MSN-RO Axially Split Multistage Pump?

The Sulzer MSN-RO is a high-efficiency , axially split , multistage centrifugal pump specifically designed for membrane feed applications in large-scale reverse osmosis (RO) desalination systems. With its advanced hydraulic design , corrosion-resistant materials , and optimized performance envelope , the MSN-RO ensures consistent high-pressure

Key Technical Specifications

Pump Type: Between-bearings , axially split , multistage centrifugal pump

Impeller Type: Closed impellers with precision-matched stages

Casing Design: Horizontally split for easy internal access and maintenance

Compliance: API 610 (BB3) adapted for desalination requirements

Materials of Construction:

– Casing: Super duplex stainless steel for superior corrosion resistance

– Impellers: Super duplex or high-grade duplex stainless steel

– Shaft: Duplex stainless steel with wear-resistant sleeves

Bearings: Sleeve and tilting-pad bearings with forced lubrication system

Sealing System: Engineered mechanical seals compatible with high-salinity water

Design & Functionality

Developed for continuous operation in high-pressure RO membrane systems

Compact and robust axially split design minimizes downtime during inspection

Stage-by-stage hydraulic optimization ensures smooth , vibration-free operation

Corrosion-resistant internals designed for aggressive seawater and brine

Easily integrates into RO skids due to flexible nozzle and baseplate configuration

Low NPSHr impeller options improve suction performance and system reliability

Typical Applications

Seawater reverse osmosis (SWRO) membrane feed systems

Municipal and industrial desalination plants

Brackish water treatment and high-salinity water processes

Offshore platform utility water production

Energy recovery loop integration in RO skids

Additional Features

Energy-efficient hydraulics reduce power consumption and operating cost

Modular design simplifies overhaul and spares management

Corrosion-resistant materials minimize maintenance in saltwater environments

Low-vibration construction increases seal and bearing life

Designed for 24/7 reliability in critical infrastructure