Description

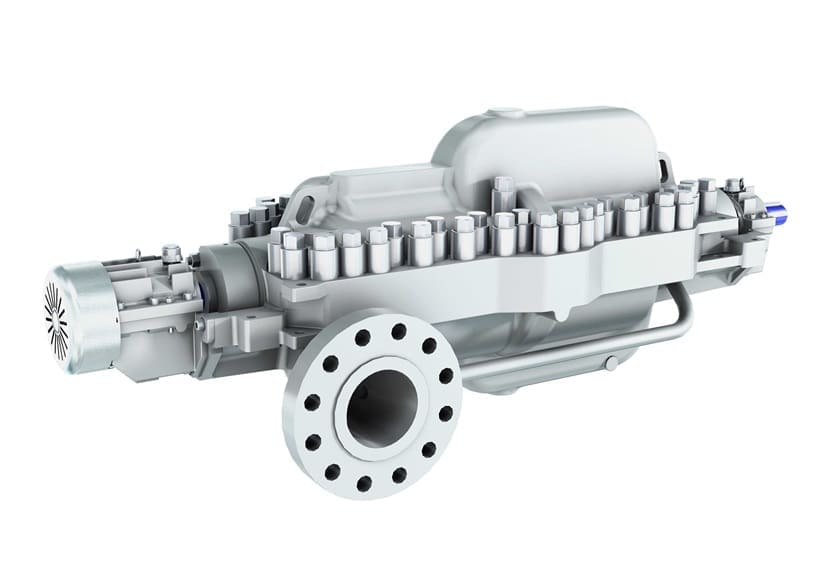

Sulzer Centrifugal Between bearing pumps MSD axially split multistage pump -The original and still unparalleled BB3 pump.

Key Technical Specifications:

| Capacities | Up to 3,200 m3/h / 14,000 US gpm |

| Heads | Up to 2,900 m / 9,500 ft |

| Pressures | Up to 300 bar / 4,400 psi |

| Temperatures | Up to 205°C / 400°F |

| Discharge sizes | 150 to 350 mm / 3 to 14 inches |

| Maximum speed of rotation | Up to 6,000 rpm |

Why Choose Sulzer MSD Axially Split Multistage Pump?

The Sulzer MSD is a high-pressure , axially split , multistage centrifugal pump designed for the most demanding applications where maximum reliability and efficiency are non-negotiable. Built to API 610 standards (BB3 type) , it delivers outstanding hydraulic performance and mechanical strength in high-pressure services , particularly in power generation , oil & gas , and desalination. Its multistage layout and robust construction ensure continuous operation under extreme conditions.

Key Technical Specifications

Pump Type: Between-bearings , axially split , multistage centrifugal pump

Impeller Type: Closed , double-suction first stage , single-suction in subsequent stages

Casing Design: Horizontally split for internal component access without disturbing pipework

Standards Compliance: API 610 (BB3) , ISO 13709

Materials of Construction:

– Casing: Carbon steel , low alloy steel , duplex stainless steel

– Impellers: Stainless steel , duplex

– Shaft: High-strength stainless steel with sleeves

Bearings: Sleeve or tilting pad bearings , oil-lubricated

Seal Options: API mechanical seal systems with standard or engineered plans

Design & Functionality

Axially split casing allows fast access for inspection and maintenance

Multistage impeller configuration delivers high differential pressure

First-stage double-suction impeller reduces NPSH requirements

Precision hydraulic balancing minimizes axial loads and wear

Optional centerline support for high-temperature stability

Optimized volute and diffuser design ensures high efficiency and low vibration

Typical Applications

Boiler feedwater systems in thermal and nuclear power plants

High-pressure water injection in oil and gas fields

Desalination (high-pressure feed or brine transfer)

Hydrocarbon processing in refineries and petrochemical plants

High-head mine dewatering systems

Additional Features

Engineered to handle extreme pressure and temperature conditions

Rigid rotor design minimizes deflection and improves seal/bearing life

Modular hydraulics for optimal performance customization

Cartridge design available for fast replacement

High efficiency and long MTBF reduce operational costs

The Sulzer MSD is the trusted choice for high-pressure pumping systems that demand maximum durability , efficiency , and uptime. Its multistage architecture , API 610 compliance , and proven performance make it ideal for critical power , oil & gas , and industrial operations where failure is not an option.