Description

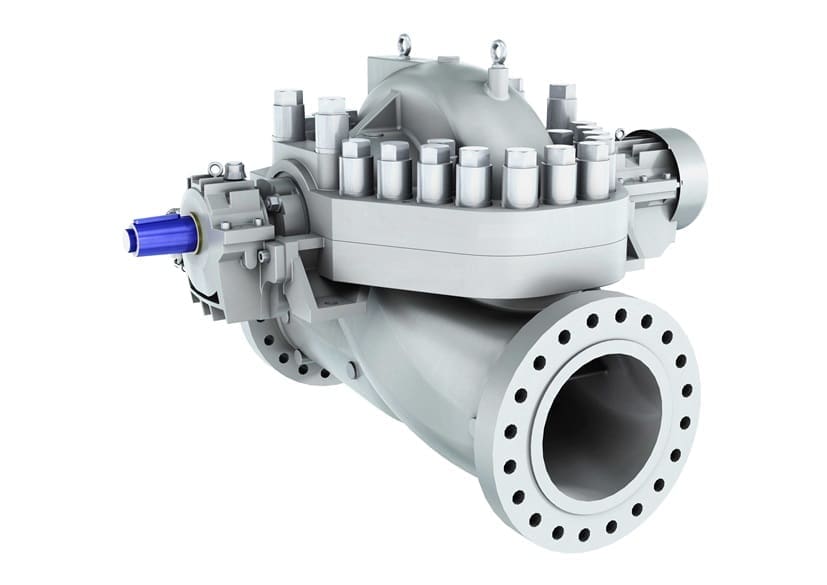

Sulzer Centrifugal Between bearing pumps HSB axially split single stage pipeline pump -The gold standard for the crude oil industry

Why Choose Sulzer HSB Axially Split Pipeline Pump?

The Sulzer HSB is a rugged , high-efficiency , axially split , single-stage between-bearing pump engineered specifically for pipeline transport of crude oil , refined products , and other hydrocarbons. Its double-suction impeller , horizontal split casing , and robust construction ensure exceptional reliability , low vibration , and simplified maintenance. Ideal for midstream and downstream oil & gas operations , the HSB pump is built to API 610 (BB1) standards for long-lasting , trouble-free performance in continuous-duty pipeline service.

Key Technical Specifications

Pump Type: Between-bearings , axially split , single-stage centrifugal pump

Casing Design: Horizontally split volute casing for pipeline installation

Impeller: Double-suction enclosed impeller , dynamically balanced

Standards Compliance: API 610 (BB1), ISO 13709

Materials of Construction:

– Casing: Carbon steel , stainless steel , duplex options

– Impeller: Stainless steel , bronze , duplex steel

– Shaft: High-tensile stainless steel

Bearings: Sleeve or rolling-element bearings with forced lubrication system

Seal Options: API Plan-compatible single or double mechanical seals

Design & Functionality

Axially split casing allows rapid inspection without disturbing pipework

Double-suction impeller minimizes axial thrust and reduces bearing wear

Symmetrical casing ensures hydraulic balance and high stability

Designed for horizontal or vertical mounting , baseplate or barrel-type configuration

Optional features: seal flush systems , bearing cooling , and condition monitoring ports

Typical Applications

Long-distance crude oil and refined product pipeline transport

Pump stations in oil & gas pipeline networks

Tank farm transfer and booster service

Water injection and seawater transport systems

Petrochemical fluid handling under high pressure

Additional Features

API 610 (BB1) compliance ensures rugged performance in oil & gas environments

High-efficiency hydraulics for reduced energy costs over extended pipeline duty

Maintenance-friendly design with quick access to rotating elements

Modular seal chamber accommodates wide range of seal plans

Heavy-duty construction suitable for remote and unmanned operation