Description

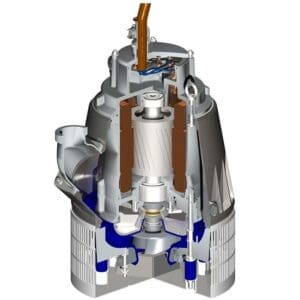

FLUITEN Mixer Mechanical Single Seals CB3Q – Single balanced cartridge seal, with springs outside the fluid, auxiliary V-ring for flushing or leakage control. Layout 02-61; 02-62. Suitable for use on side-mounted or bottom-entry agitators and with liquids that tend to solidify and crystallize in contact with the atmosphere.

Key Technical Specifications:

| DIAMETER | SPEED | PRESSURE | TEMPERATURE |

|---|---|---|---|

| 20-90 (mm)* | 0-12 (m/sec) | 0-25 (bar) | -50 ÷ 250 (°C) |

Why Choose FLUITEN CB3Q?

The CB3Q is a hydraulically double-balanced single cartridge seal, optimized for use on mixers, dryers, mills, or side-entry agitators handling fluids that tend to crystallize upon contact with air. It includes a continuous quench containment ring (V-ring) and a reinforced thick sleeve to handle higher shaft run‑out directly from the machine shaft, providing robust sealing in high-cleaning and high-vibration environments.

Key Technical Specifications

Seal Type: Single cartridge seal with dual hydraulic balance and auxiliary V-ring quench containment

Stationary Ring Materials: Solid graphite, sintered silicon carbide, tungsten carbide, or dry-running graphite option for vapor service

Rotating Ring Materials: Integral silicon carbide or tungsten carbide

Elastomer Seals: FKM, EPDM, or perfluoroelastomer gaskets on rotary ring, stationary ring, and the product-side sleeve

Containing V‑Ring: External quench containment seal to manage continuous flushing or wash-down fluids

Spring System: External AISI 316 springs placed outside the process fluid zone

Drive Mechanism: Sliding-drive rotor maintains contact with the rotating ring under axial, radial, or vibration‑induced movement

Sleeve & Flange Design: Extra-thick sleeve to tolerate high shaft run‑out; slotted flange adapts to various stuffing-box configurations

Flush Connections: Threaded quench/flushing ports for barrier or cooling fluids (Plan‑type interface)

Operating Limits (typical ranges)

Shaft diameter: approximately 25–90 mm

Rotary speed: up to 12 m/s

Pressure rating: up to 25 bar(g)

Temperature range: −50 °C to +250 °C

Typical Applications

Mixers and small agitators (side- or bottom-mounted) processing viscous, clean or crystallizing fluids, requiring external wash or quench

Direct shaft-mounted applications—mills , dryers , or machines with no stuffing-box sleeve , but with high shaft run‑out

Industrial sectors such as food processing, chemical mixing, and pharmaceuticals where leakage control and periodic cleaning are essential

Additional Features

External springs avoid product buildup and simplify cleaning in hygienic environments

Double-balanced design resists pressure reversals and prevents face separation under dynamic loads

Quench V‑ring enables continuous flushing without contaminating process fluid

Self-centering Fluistrip tool simplifies installation and ensures proper alignment prior to machine start-up

Heavy-duty sleeve and resilient drive mechanism maintain performance in high-vibration or misaligned shaft conditions

The FLUITEN CB3Q offers a high-reliability sealing solution for mixers and light rotary machinery handling fluids that crystallize or require periodic wash-down. With its double hydraulic balance, quench containment ring, reinforced sleeve, and dynamic drive stability, it delivers dependable performance in demanding, contamination-sensitive operations.