Description

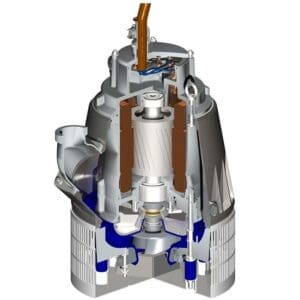

FLUITEN Mixer Mechanical Single Seals CB3S – Single balanced seal. Suitable for side-mounted agitators and use with harmless and moderately dirty liquids.

Key Technical Specifications:

| DIAMETER | SPEED | PRESSURE | TEMPERATURE |

|---|---|---|---|

| 20-90 (mm)* | 0-12 (m/sec) | 0-25 (bar) | -50 ÷ 250 (°C) |

Why Choose FLUITEN CB3S?

CB3S is a double-hydraulically balanced single cartridge seal designed for mixers, small agitators, mills, and dryers. It features springs located outside the product fluid and a reinforced thick sleeve to tolerate shaft run‑out, ensuring durability in equipment with misalignment or vibration. The seal is easy to install using the Fluistrip centering tool and slotted flange assembly.

Key Technical Specifications

Seal Type: Single balanced cartridge seal with double hydraulic balance

Stationary Ring Materials: Graphite, silicon carbide, or tungsten carbide

Rotating Ring Materials: Silicon carbide or tungsten carbide

Gaskets: Gasket options in FKM, EPDM, or FFKM for rotating ring, stationary ring, sleeve, and flange

Springs: Hastelloy springs situated outside of the process fluid

Drive System: Sliding-drive mechanism maintains seal-face contact under shaft movement and wear

Sleeve & Flange: Extra-thick sleeve accommodates high shaft run‑out; slotted flange fits multiple stuffing-box configurations

Fluistrip Device: Self-centering installation tool, removed before machine start-up

Flush Options: Threaded flushing connections available via pump discharge (Plan 11) or external source (Plan 32)

Typical Applications

Light and medium-duty mixers, agitators, dryers, and mills

Side-entry or bottom-entry mixers with moderately clean fluids

Equipment subject to shaft misalignment or run‑out, where robust sealing is required

Installations where fast, accurate installation and minimal maintenance are valued

Additional Features

Double-balanced hydraulics prevent face separation during pressure reversals

Sliding-drive rotor compensates for shaft movement and maintains performance

Fluistrip tool and slotted flange simplify retrofitting to varied pump/mixer housings

Reinforced sleeve design resists deformation in high run‑out conditions

Optional flush ports (Plan 11 or Plan 32) add versatility for flushing requirements