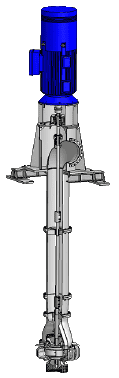

Description

Sundyne Pump API VS2 vertically suspended double volute centrifugal pump, wet pit, with single casing-Featuring a double-volute design built to API 610 standards, it delivers smooth, low-NPSH operation in submerged conditions.

Key Technical Specifications:

- Flows to 39,600 gpm (10,000 m³/hr)

- Heads to 490 ft (150 m)

- Maximum Power 2,012 Hz (1,500 kW)

- Maximum Case Working Pressure 218psi (15 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)

Why Choose the VS1?

The VS1 is your go-to pump when you need high-pressure performance directly from a sump or wet pit without priming. As a vertically suspended, multistage diffuser pump with a single casing, it meets API 610 and ISO 13709 standards. Engineered to combine high flow (up to 13,209 US gpm) with heads up to 1,150 ft, and suitable for pit depths up to 40 ft, it’s built for heavy-duty applications in refineries, power generation, desalination, tank farms, and offshore platforms

Main Features

Vertically suspended design with submerged bowl and above-ground drive—no priming needed

innopumps.com

Radially split single casing including diffuser—to simplify maintenance .

Flexible coupling and mounting flange, with column bearings lubricated by pumped fluid

Multi-stage diffuser hydraulics—low NPSH design in first-stage impeller enables pumping at low inlet pressures

Seal chamber per API 682, with mechanical seals as standard; optional cartridge kits too

Bearings include thrust-bearing housing above the column and column support bearings lubricated by fluid

Applications

Designed for demanding services such as:

Refineries & petrochemical processes

Cooling , condensing , and boiler-feed water systems in power plants

Desalination and reverse-osmosis booster duties

Tank-drain, flood-control, condensate extraction, sump and fire-protection pumping

Offshore/inland platform wet pits and tank farms