Description

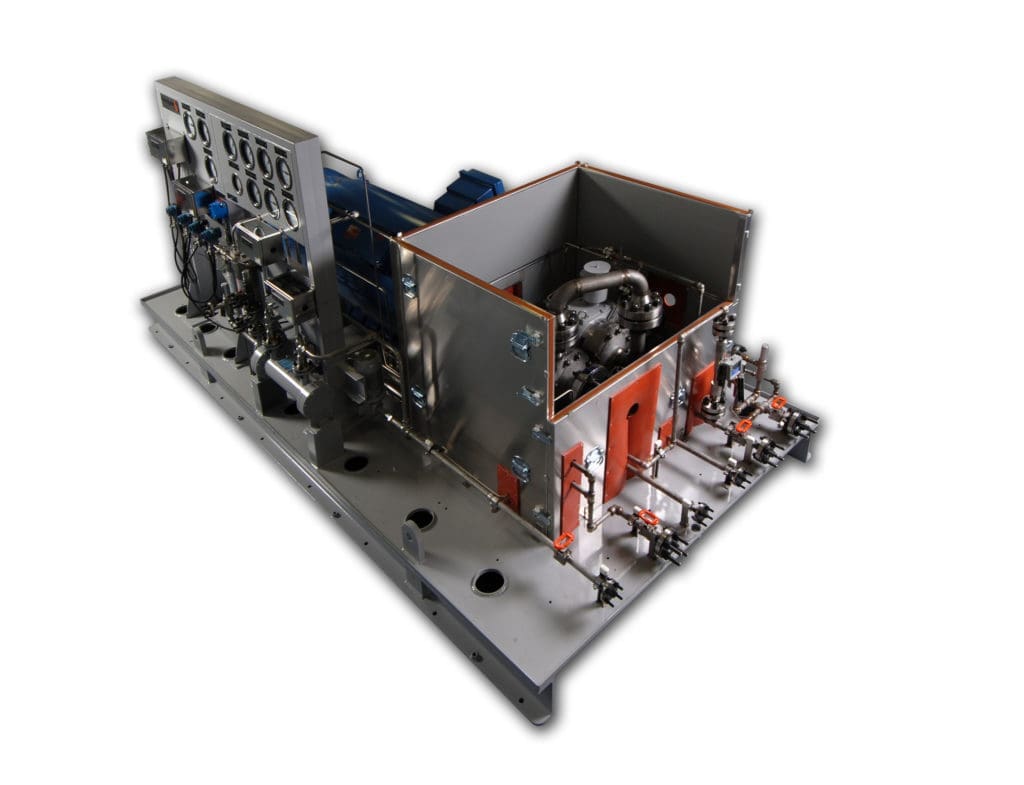

Sundyne Pump Centrifugal HMP 3000 Multi-Stage Integrally Geared Pump-ompact size , rugged reliability , and energy-efficient operation in high-pressure applications.

Key Technical Specifications:

- Flows to 440 gpm (100 m³/hr)

- Heads to 10,000 ft (3,050 m)

- Maximum Power 800 HP (600 kW)

- Maximum Suction Pressure 425 psi (30 bar)

- Minimum NPSH

- Temperature Range -200 to 500°F (-130 to 260°C)

Why Choose the HMP 3000?

Opt for the HMP 3000 when you require a compact, heavy-duty, high-pressure machine for critical low-flow, high-head services in industries like urea, fertilizer, PTA, and petrochemicals. Its two-stage overhung impeller design, driven by a single gearbox and motor, reduces footprint by about 75% compared to conventional pumps. Computer-optimized hydraulics ensure your pump operates efficiently at the best efficiency point (BEP) while delivering reliable performance for up to five years without overhaulMain Features

Compact integrally geared design packs up to two stages into a small horizontal layoutCustom hydraulics with Barske impellers and optimized diffusers for maximum efficiency and low NPSHr

ATEX-rated for operation in hazardous areas

Minimal maintenance thanks to robust gearbox and impeller design—5 years of continuous run time without major overhaul

Sundyne Pumps and CompressorsEfficient power use: tailored hydraulics lower end-of-curve horsepower, enabling smaller motor sizes and energy savings

- Applications

Engineered for precision in high-head, low-flow services such as:Fertilizer and urea processing (e.g., ammonia synthesis feed)Purified Terephthalic Acid (PTA) slurry pumpingHigh-pressure hydrocarbon feed , propylene service

Pressure booster systems in petrochemical and refinement plants

Choose the HMP 3000 . The bespoke hydraulics , Barske impellers , ATEX rating , and minimal maintenance needs deliver unmatched performance-staying efficient at BEP and offering up to five years between overhauls-all backed by Sundyne’s global engineering support.