Description

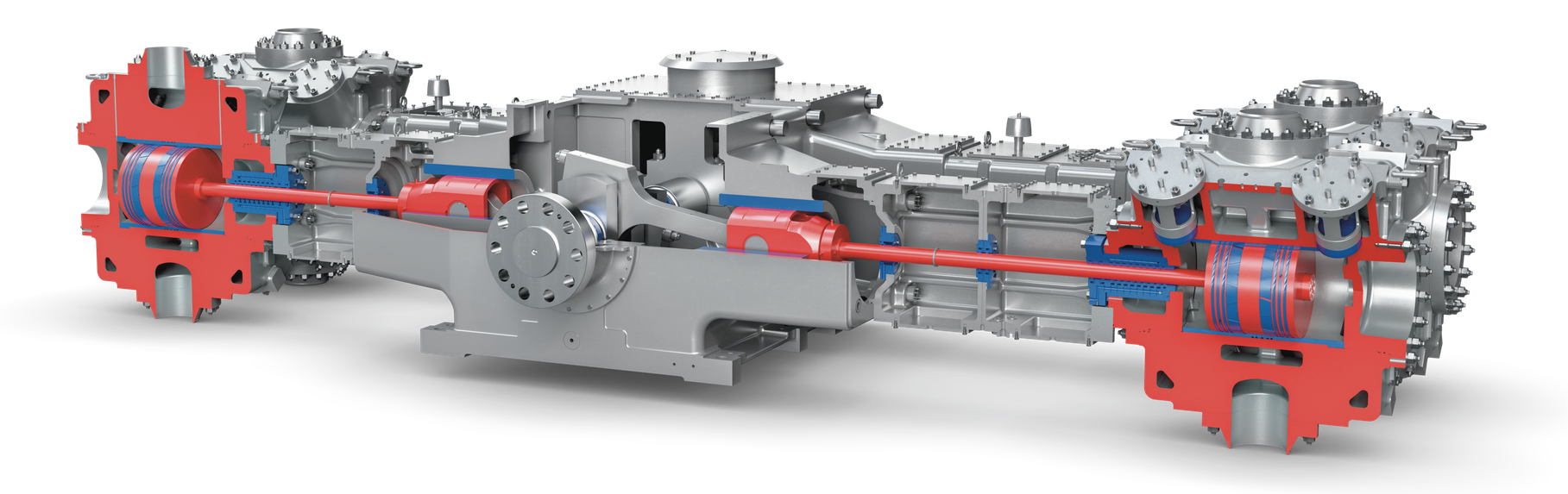

Burckhardt Compression D/M 25 Horizontal Process Gas Compressor – Heavy – Duty Solution for Demanding Process Gas Applications

Key Technical Specifications:

Compressor Type: D/M 25

Maximum Speed: 420 rpm

Rated Power: 3’378 kW / 4’530 hp

Maximum Rod Load: 275 kN / 61’823 lbs

Design Standards: API 618, ISO 13707

Configuration: Horizontal , reciprocating , multi – throw

Crankcase Type: Gas – tight, high – integrity frame

Cooling System: Water – cooled for frame and cylinder heads

Why Choose the Burckhardt D/M 25 Compressor?

Built for Demanding Conditions

With over 3,300 kW (4,500+ hp) output and 275 kN rod load capacity , the D/M 25 is made for high -pressure , continuous – duty applications.

Safe for Tough Gases

Gas – tight design makes it ideal for flammable , corrosive , or toxic gases – delivering power with peace of mind.

API 618 Certified

Fully compliant for use in critical , high – risk environments across global industries.

Customizable & Scalable

Supports multi – stage setups and modular cylinders to fit complex process needs.

Ideal Applications

Petrochemical and refinery gas systems

High – pressure hydrogen , CO₂ , and syngas compression

Gas injection , storage & recovery

Ammonia , methanol , and urea production

Pipeline booster stations

Key Features

Heavy – duty, cast – iron frame for low vibration

Long service intervals , minimal wear parts

Optional condition monitoring for predictive maintenance

Optimized for remote or unmanned operation